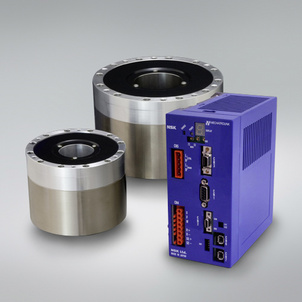

NSK Adds MECHATROLINK Driver Unit to Megatorque Motor™ Lineup

January 18, 2012—

NSK Ltd. announced that it will add a new MECHATROLINK-driver unit *(1) to its popular Megatorque Motor™ lineup. The Megatorque Motor™ is capable of compact, high speed positioning. Combined with a MECHATROLINK function, it is able to achieve integrated control and high-speed synchronized operation using high-speed communication with multiple devices such as other motors and sensors via a MECHATROLINK network. Thus, it can help improve productivity and shorten startup time. The product will go on sale in March 2012, and NSK targets 500 million yen in sales in 2014.

Development background

The field network is a commonly used technology to reduce the amount of wiring between peripheral devices in order to achieve more advanced and sophisticated manufacturing systems. In recent years, there has been an increase in the expectation for motion field network technology, which enables not only the peripheral devices such as sensors to communicate, but also the motors and actuators to achieve high-speed synchronized motion.

MECHATROLINK-III *(2) has the latest motion field network specifications with a communication speed of 100 Mbps. This capability makes it possible to achieve high-speed synchronized operation and integrated control of multiple motors and peripheral devices. With it, users can take full advantage of the advanced positioning performance and compactness of the Megatorque Motor lineup, which results in shorter equipment startup time and shorter operation sequences for every manufacturing process, which translates to a dramatic improvement in production efficiency. Furthermore, this means a higher level of equipment integration is possible, and it makes equipment more valuable in terms of energy savings, compactness, and reliability.

Product features

1. Multi-axis, high-speed synchronized operation made easy

The synchronization delay between multiple motors is extremely low (transfer rate of 250 μs),

which means high-speed, high-precision linked operations are possible. Combination with linear motion products makes it easy to achieve operations involving complex curved and spiral trajectories.

2. Advanced rotational operation by flexible control switching

Possible to consecutively change the control mode between position, velocity and torque while rotating. No need to pause or wait for switching control modes.

3. Reduced wiring, and improved communication reliability

Synchronization signal wiring is integrated into the communication wiring. This means less wiring for greater integration. It also ensures secure communication for motion control, so that the equipment itself obtains higher reliability and production quality.

Major Applications

Semiconductor and LCD panel manufacturing equipment

Electronics and automotive parts manufacturing equipment

Lithium ion secondary batteries (LIB) film and metal foil wrapping machines

Medical product packaging (PTP packaging) and food product

Benefits

Improved productivity

High-speed synchronized operation of multiple motor axes

Precision torque control

Faster molding feed times and faster precision positioning control

*(1) Driver unit: Controller used to drive Megatorque Motor.

*(2): MECHATROLINK-III

MECHATROLINK is an open protocol that many production equipment manufacturers have adopted.

MECHATROLINK-III provides extremely high-speed communication performance, making it possible to synchronously operate 11 motor axes at a transfer rate of 250 μs. That is 10 times the communication speed and 11 times the number of motor axes that can be synchronized (at a transfer rate of 250 μs) compared to MECHATROLINK-II.

“MECHATROLINK” is a trademark of the MECHATROLINK Members Association.

January 18, 2012—

NSK Ltd. announced that it will add a new MECHATROLINK-driver unit *(1) to its popular Megatorque Motor™ lineup. The Megatorque Motor™ is capable of compact, high speed positioning. Combined with a MECHATROLINK function, it is able to achieve integrated control and high-speed synchronized operation using high-speed communication with multiple devices such as other motors and sensors via a MECHATROLINK network. Thus, it can help improve productivity and shorten startup time. The product will go on sale in March 2012, and NSK targets 500 million yen in sales in 2014.

Development background

The field network is a commonly used technology to reduce the amount of wiring between peripheral devices in order to achieve more advanced and sophisticated manufacturing systems. In recent years, there has been an increase in the expectation for motion field network technology, which enables not only the peripheral devices such as sensors to communicate, but also the motors and actuators to achieve high-speed synchronized motion.

MECHATROLINK-III *(2) has the latest motion field network specifications with a communication speed of 100 Mbps. This capability makes it possible to achieve high-speed synchronized operation and integrated control of multiple motors and peripheral devices. With it, users can take full advantage of the advanced positioning performance and compactness of the Megatorque Motor lineup, which results in shorter equipment startup time and shorter operation sequences for every manufacturing process, which translates to a dramatic improvement in production efficiency. Furthermore, this means a higher level of equipment integration is possible, and it makes equipment more valuable in terms of energy savings, compactness, and reliability.

Product features

1. Multi-axis, high-speed synchronized operation made easy

The synchronization delay between multiple motors is extremely low (transfer rate of 250 μs),

which means high-speed, high-precision linked operations are possible. Combination with linear motion products makes it easy to achieve operations involving complex curved and spiral trajectories.

2. Advanced rotational operation by flexible control switching

Possible to consecutively change the control mode between position, velocity and torque while rotating. No need to pause or wait for switching control modes.

3. Reduced wiring, and improved communication reliability

Synchronization signal wiring is integrated into the communication wiring. This means less wiring for greater integration. It also ensures secure communication for motion control, so that the equipment itself obtains higher reliability and production quality.

Major Applications

Semiconductor and LCD panel manufacturing equipment

Electronics and automotive parts manufacturing equipment

Lithium ion secondary batteries (LIB) film and metal foil wrapping machines

Medical product packaging (PTP packaging) and food product

Benefits

Improved productivity

High-speed synchronized operation of multiple motor axes

Precision torque control

Faster molding feed times and faster precision positioning control

*(1) Driver unit: Controller used to drive Megatorque Motor.

*(2): MECHATROLINK-III

MECHATROLINK is an open protocol that many production equipment manufacturers have adopted.

MECHATROLINK-III provides extremely high-speed communication performance, making it possible to synchronously operate 11 motor axes at a transfer rate of 250 μs. That is 10 times the communication speed and 11 times the number of motor axes that can be synchronized (at a transfer rate of 250 μs) compared to MECHATROLINK-II.

“MECHATROLINK” is a trademark of the MECHATROLINK Members Association.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Linear Motion Solutions on Display at MD&M West 2012

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.