A modular system from Igus for new ideas

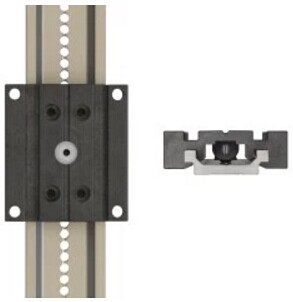

drylin W special solution with customised grid system. A ball catch ensures the fixing of the carriage on the rail.

Tribologically optimised high-performance plastics allow the use of the igus drylin linear plain bearings without any additional lubrication. They provide a smooth and easy-to-run operation, without any dirt particles sticking to it. They are extremely clean, robust, corrosion-free, light and cost-effective. The wide range of rail and liner combinations offered here enable designers to assemble their solutions according to their individual requirements from the wide range of options in the modular system.

Most varied rail materials

The standard material for rails in the drylin modular system is hard anodised aluminium, which achieves the best coefficient of friction as a running surface in combination with iglidur materials. For more specialised applications, however, the drylin W modular system also offers more specialised materials such as stainless steel, which is resistant to chemicals or salt water. At the 2015 Hannover Messe igus also introduced a linear guide with a rail made entirely of carbon fibre-reinforced plastic.

“The strengths of the so-called carbon are obvious,” says Stefan Niermann, head of the drylin linear and drive technology business unit at igus. “It is extremely light, non-magnetic and is characterised by a high rigidity.”

For applications where these properties are required, for example in the aircraft or the medical industry, igus now offers the lightest linear guide in the world. It is designed for up to 2000 mm stroke. Since the entire rail is made from carbon, the weight saving is considerable.

drylin W special solution with customised grid system. A ball catch ensures the fixing of the carriage on the rail.

Tribologically optimised high-performance plastics allow the use of the igus drylin linear plain bearings without any additional lubrication. They provide a smooth and easy-to-run operation, without any dirt particles sticking to it. They are extremely clean, robust, corrosion-free, light and cost-effective. The wide range of rail and liner combinations offered here enable designers to assemble their solutions according to their individual requirements from the wide range of options in the modular system.

Most varied rail materials

The standard material for rails in the drylin modular system is hard anodised aluminium, which achieves the best coefficient of friction as a running surface in combination with iglidur materials. For more specialised applications, however, the drylin W modular system also offers more specialised materials such as stainless steel, which is resistant to chemicals or salt water. At the 2015 Hannover Messe igus also introduced a linear guide with a rail made entirely of carbon fibre-reinforced plastic.

“The strengths of the so-called carbon are obvious,” says Stefan Niermann, head of the drylin linear and drive technology business unit at igus. “It is extremely light, non-magnetic and is characterised by a high rigidity.”

For applications where these properties are required, for example in the aircraft or the medical industry, igus now offers the lightest linear guide in the world. It is designed for up to 2000 mm stroke. Since the entire rail is made from carbon, the weight saving is considerable.

The applications that are implemented with drylin W are as diverse as the huge variety in the modular kit. Whether for use in a saw in woodworking or in camera sliders.

Drawer open: Suitable iglidur material for any application

For different applications, not only different rail materials are needed but also various plastics as liners. Thus there are drawers with five different iglidur materials in the drylin W modular kit at igus. For example, the FDA-compliant material iglidur A180, the endurance runner on steel and stainless steel shafts iglidur E7, or iglidur X for extreme temperatures from -100°C to + +250°C.

This achieves optimum friction coefficients on hard-chromed steel and reaches the highest service life on hardened stainless steel. All materials are available as liners that can be clipped into the housing bearing. An open geometry and axial securing also facilitate the assembly and ensure the positive location of the liner in the housing.

New drawers are added constantly for even more freedom

Further innovations, such as manual clamps, complete the drylin W modular system. With this, the carriage can be hand fitted easily. This simple solution can be retrofitted even in existing systems. Further features include unique solutions. The new products of this year within the drylin W family, include linear guides that enable curve-shaped travel. This paves the way for completely new design concepts. The guide rails for curves are made of aluminium with an exceptionally resistant, hard anodised coating. Customised carriages enable travel along curved rails with a smooth motion.

The driver’s cabin of a farm machine is a good example of how curved guide rails can increase the flexibility in the adjustment of monitors, seats and fixtures. Within certain physical limits, users can choose their own radius and achieve the perfect fit in the driver’s cabin. The special feature of the drylin W modular system has always been that you can open up new drawers and offer new solutions. For example, a complete solution with pre-drilled grid system. This enables the perfect and quick positioning of the carriage . A ball catch on the underside of the carriage ensures the gradual interlocking.

The modular system becomes smart

This year, igus takes another step with the drylin W linear modular kit and at the Motek displays the opportunities that arise from the intelligent networking of the products. These networked smart plastics expand the possibilities for so-called predictive maintenance and increase the plant availability for the customer. Intelligent drylin linear guides constantly monitor themselves and provide an early warning of failure. The range named isense consists of different sensors and monitoring modules. By networking with the igus communication module (ICOM), a direct integration with the customer’s infrastructure takes place.The isense is able to monitor the service life of the linear guide in use.

Through continuous distance measurements and the calculations using the parameters of the system as well as the test data from the laboratory, it is possible to also reliably predict the operation. If measured values are exceeded, the intelligent products indicate the remaining term of use early, which enables a timely maintenance and replacement.

As an option isense can be connected to the igus data centre, opening up more digital options: customised service life calculation and optimisation of business processes. These include maintenance commissioning or spare parts ordering. In this way, the electronic intelligence lowers maintenance costs even further and increases plant availability.

The applications that are implemented with drylin W are as diverse as the huge variety in the modular kit. Whether for use in a saw in woodworking or in camera sliders.

Drawer open: Suitable iglidur material for any application

For different applications, not only different rail materials are needed but also various plastics as liners. Thus there are drawers with five different iglidur materials in the drylin W modular kit at igus. For example, the FDA-compliant material iglidur A180, the endurance runner on steel and stainless steel shafts iglidur E7, or iglidur X for extreme temperatures from -100°C to + +250°C.

This achieves optimum friction coefficients on hard-chromed steel and reaches the highest service life on hardened stainless steel. All materials are available as liners that can be clipped into the housing bearing. An open geometry and axial securing also facilitate the assembly and ensure the positive location of the liner in the housing.

New drawers are added constantly for even more freedom

Further innovations, such as manual clamps, complete the drylin W modular system. With this, the carriage can be hand fitted easily. This simple solution can be retrofitted even in existing systems. Further features include unique solutions. The new products of this year within the drylin W family, include linear guides that enable curve-shaped travel. This paves the way for completely new design concepts. The guide rails for curves are made of aluminium with an exceptionally resistant, hard anodised coating. Customised carriages enable travel along curved rails with a smooth motion.

The driver’s cabin of a farm machine is a good example of how curved guide rails can increase the flexibility in the adjustment of monitors, seats and fixtures. Within certain physical limits, users can choose their own radius and achieve the perfect fit in the driver’s cabin. The special feature of the drylin W modular system has always been that you can open up new drawers and offer new solutions. For example, a complete solution with pre-drilled grid system. This enables the perfect and quick positioning of the carriage . A ball catch on the underside of the carriage ensures the gradual interlocking.

The modular system becomes smart

This year, igus takes another step with the drylin W linear modular kit and at the Motek displays the opportunities that arise from the intelligent networking of the products. These networked smart plastics expand the possibilities for so-called predictive maintenance and increase the plant availability for the customer. Intelligent drylin linear guides constantly monitor themselves and provide an early warning of failure. The range named isense consists of different sensors and monitoring modules. By networking with the igus communication module (ICOM), a direct integration with the customer’s infrastructure takes place.The isense is able to monitor the service life of the linear guide in use.

Through continuous distance measurements and the calculations using the parameters of the system as well as the test data from the laboratory, it is possible to also reliably predict the operation. If measured values are exceeded, the intelligent products indicate the remaining term of use early, which enables a timely maintenance and replacement.

As an option isense can be connected to the igus data centre, opening up more digital options: customised service life calculation and optimisation of business processes. These include maintenance commissioning or spare parts ordering. In this way, the electronic intelligence lowers maintenance costs even further and increases plant availability.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Maria-Elisabeth Schaeffler-Thumann receives the Global Leadership Award from the American Institute for Contemporary German Studies (AICGS)

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.