IKO OFFERS LINEAR GUIDES FOR ROBOTICS COMPETITION

A team of middle- and high-school students in Gibsonton, Florida are showing off their math and science skills by designing, building and programming a competitive robot using IKO International linear guides. With IKO in their corner, the team is outscoring rivals and setting records along the way. They call themselves Neutrinos 6433, and the team competes in the FIRST Tech Challenge at a Central Florida tournament held in Lakeland, Florida. FIRST (For Inspiration and Recognition of Science and Technology) inspires innovation and leadership in young people through engaging, team-based robotics challenges. The challenges are designed to demonstrate the accuracy, timing and precision of the robot. For example, one match pitted four robots against each other inside a ring. Competitors were given a task that tested their robots’ ability to maneuver around the ring, and to grasp, arrange and stack Lego-like blocks.

The Neutrinos 6433 team discovered IKO while researching potential linear motion guides to design into the robot. IKO International sponsored the Neutrinos 6433 team and supplied the linear motion guides that helped lead the robot to victory. IKO was also available to mentor Neutrinos 6433, and the team tackled their challenges with little assistance, using the following IKO motion guides:

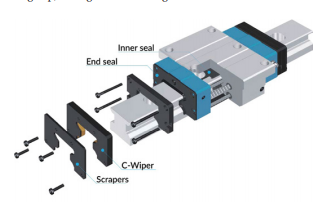

MX linear motion guide. One of the highest performing and dependable guides available. The MX Series guide features a slide unit that operates on a balanced set of four cylindrical rollers housed in a rigid casing, giving it high load capacity and exceptional stiffness and resistance to moment loads. This construction maximizes accuracy, produces a more compact design than ball-type units, and it gives the robot its streamlined size and excellent maneuverability. The MX Series is available in four different lengths—including an extra-long unit MXL that’s 1.4 times the standard slide unit length—so the students were able to achieve long extensions to stack items with smoothness and precision. The MX Series also offers a high load capacity and C-Lube technology for long-term, maintenance-free operation—because when you’re battling for robotic supremacy, you can’t slow down to lubricate your guide.

LWL linear motion rolling guide. The LWL Series incorporates two rows of stainless-steel balls arranged in a fourpoint contact design with the raceways. Although small, it provides stable accuracy and rigidity due to its simple design even in operations under fluctuating loads with changing direction and size or complex loads. LWF linear motion rolling guide. This series provides continuous linear motion thanks to a wide track rail and highly rigid slide unit. Two rows of large-diameter steel balls and a four-point contact design with the raceways ensure high stability and accuracy, even under fluctuating and complex loads. The wide rail also supports large moment loads in the axial direction.

The results have been impressive! While Neutrinos teams have performed well in their previous eight years in the Challenge, this year’s team made significant gains. Neutrinos 6433 achieved front-runner status, boasting the highest scores and highest average score among the other 20 participating teams. Not only did Neutrinos 6433 produce high scores, they also posted back-to-back world record scores before being eclipsed by another team. As of this writing, Neutrinos 6433 have the highest average score among teams from around the country. That’s no small feat! Thanks to their hard work, skill and determination plus exceptional linear guides from IKO, Neutrinos 6433 is clearly the team to beat.

Dassault Systèmes and Xometry recently announced their partnership to provide customers with a seamless, integrated way to produce parts that accelerates the concept to manufacturing process. Engineers using Dassault Systèmes’ Solidworks and Catia applications will have automatic and immediate access to Xometry price quotes on MAKE Marketplace for manufacturing parts, without leaving their design environment.

Engineers can now play a greater role in the design to manufacturing aspect of part production by focusing on the shape of a prototype as well as the cost to produce it. Whereas sourcing manufacturing price quotes from service providers used to require a dozen clicks in a web interface, it now takes place instantaneously in a one-click immersive experience integrated with Solidworks and Catia. Engineers can view Xometry price quotes on their screen in the context of their design, and click to have it manufactured, all while retaining the option to get instant or manual quotes from other MAKE Marketplace suppliers. “We launched the MAKE Marketplace in 2018 to make it easy for customers to design and manufacture. Our partnership with Xometry takes this a step further,” said Sébastien Massart, head of corporate strategy, Dassault Systèmes. “Customers can order high quality additive manufacturing or CNC machining parts in one click at the right price, thanks to Xometry instant quoting capabilities. This is all part of our vision to continuously reduce the friction that customers face going from design to manufacturing.” Through this partnership, Xometry becomes the first “prime partner” of Dassault Systèmes’ MAKE Marketplace. This new category recognizes qualified service providers having industrial-grade quality certifications, and production capacities to answer demanding needs as well as high satisfaction rates. Dassault Systèmes plans to add other “prime partners” to the 3DEXPERIENCE Marketplace ecosystem. “Engineers need the right tools to do their job successfully, and this includes working with a responsive, trusted manufacturing partner,” said Randy Altschuler, CEO, Xometry. “As the leader in 3D printing and on-demand manufacturing, we have served many customers in the MAKE Marketplace since its launch. Through our deeper partnership with Dassault Systèmes, we can directly connect with customers and make a commitment to provide a quote on every customer query. It’s all about faster manufacturing.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next KISSsoft Offers Software to Students

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.