Condition Monitoring Technology Evolves for Gear Drives, Gearmotors and Gearboxes

Life is full of planned and unplanned activities. Sometimes we embrace those unplanned moments (character-builders some might say), but we also feel a sense of real satisfaction when everything goes according to plan. In the manufacturing world where gear drives and gearmotors are supposed to do exactly as they’re told, the unplanned activities could increase costs, cause equipment failures, and stop production altogether. Thankfully, advances in IIoT and smart manufacturing are making it easier every year to eliminate unplanned occurrences on the shop floor. “Every asset may have a different critical component. In some applications, the gearbox might be the most critical. In other applications, it may be the motor, a bearing, or multiple gearboxes or motors,” said Dan Phillips, director, Perceptiv Technologies at Regal Beloit. “Having a scalable system allows for the flexibility to monitor all the components within an asset. In some instances, if a gearbox experiences a failure, the motor or bearings may need to be replaced if the failure is severe and causes damage to these components. Monitoring multiple components provides insight to make the necessary improvements based on data. Additionally, a scalable system allows a user to expand the system to adjacent power transmission applications instead of having to invest in different technology.” The following article examines a few of the condition monitoring systems available in the PT market that help shop personnel stay ahead of unplanned activities regarding gear drives, gearboxes and gearmotors. With an emphasis on smart manufacturing, these tools stay ahead of operation failures, provide real-time data to make better informed maintenance decisions, reduce service and material costs and provide longer service life not just for individual components but entire mechanical systems.

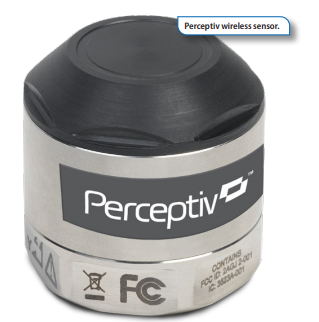

Regal Offers Wireless Condition Monitoring Solution

The Perceptiv wireless monitoring system is an evolution for Regal’s diagnostics and services team. It was launched based on feedback from customers who needed an easy-to-use, expandable wireless vibration and temperature monitoring system for their gearboxes, bearings and motors. Unlike other wireless systems that provide only “basic” diagnostic data, the Perceptiv monitoring system delivers full waveform and spectral data to provide better predictive capabilities. This data is multi-functional—vibration and temperature analysis, for example. It is adaptable to any industry or equipment and scalable (25 nodes per gateway). Operator safety is vital as it eliminates the need to be near the equipment. It’s also cost-effective, providing a simple installation that allows the operator to monitor many different assets. In addition, the data visualization is web-based, the platform can be located on-site or in the cloud, and the battery offers a two-year lifespan. “Regal’s technology continues to evolve with our customers. We offer a variety of technologies to align with the needs of our customers’ changing businesses and infrastructures,” Phillips said. “Not too long ago, wired systems were the norm. With the advent of 5G and improvements to communication equipment, we see more and more wireless capabilities driving data to a secure cloud, which allows monitoring from the comfort of your home while being able to keep an eye on your equipment or a plant’s operations.” Phillips said that Regal can monitor vibration, strain, temperature, power and current voltage. “This toolset allows us to obtain torque, speed, efficiency and reliability data, which ties back to tons, bottles and cartons per hour for our customers. To help make this easier for customers, we use augmented reality. It allows users to look at equipment on a tablet or smartphone to monitor equipment conditions. With just the scroll of a finger, they can peel back equipment layers to look at critical components, read bills of materials, and gain a better understanding,” he added.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Dynamic Behavior of Planetary Gears

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.