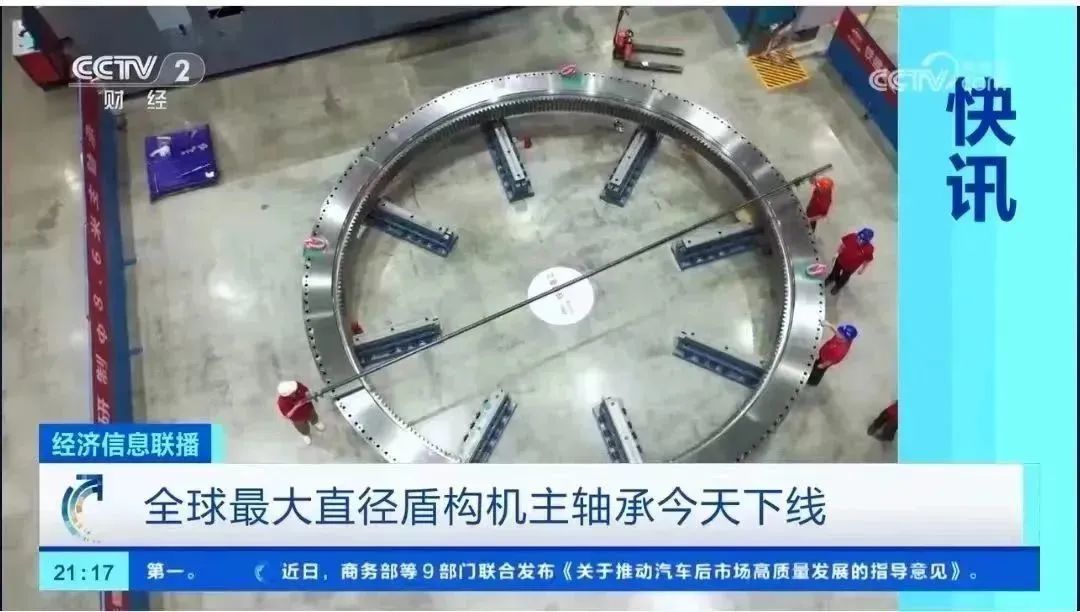

The world's largest diameter shield machine main bearing comes off the production line today

The world's largest-diameter shield machine main bearing independently developed by China has rolled off the production line. This marks that the domestically produced ultra-large-diameter main bearings have reached the world's leading level in research and development capabilities, and have realized the full range of domestically produced shield machine main bearings from small to medium diameters to ultra-large diameters cover!

The main bearing of the largest diameter shield machine has a diameter of 8.61 meters. It can drive an 18-meter super-large diameter shield machine. It has a dead weight of 62 tons and can withstand a load of over 10,000 tons. In a pipeline of more than 8 meters, the flatness of the plane is less than 20 microns. The precision is no less than that of engraving on grains of rice. The main bearing of the shield machine is precision manufactured. The precision level determines the service life. The flatness requirement is less than 20 microns, which is equivalent to 1/5 of the thickness of an A4 paper. , the main bearing is the heart of the shield machine and cannot be replaced in the tunnel. It determines the performance and life of the shield machine. It is at the top of large high-end bearings. The difficulty of development increases exponentially as the size increases!

Stu assists in the manufacturing of main bearings for the world's largest shield machine

Stu robot grinding and chamfering equipment is used for chamfering and grinding large gears in the wind power and engineering machinery industries. The traditional manual grinding method has low efficiency, poor appearance, and uncontrollable quality. Using CNC milling machines to grind chamfers cannot meet the needs of gear applications of different sizes. The efficiency is low and the equipment is expensive. Stu robot grinding and chamfering equipment perfectly solves the above industries. Pain points!

Stu robot grinding and chamfering equipment is the world's first automated equipment that integrates tooth chamfering and quenching soft belt grinding technology (there are currently only 2-3 companies in the industry that realize single-function automation). After manual loading and unloading, the equipment can automatically implement ring gear chamfering, tool changing, quenching soft belt grinding and dust removal, etc., which can effectively increase processing time and reduce labor intensity. Taking a main bearing with a diameter of 4.8m as an example, the original artificial tooth chamfering requires 16-18 hours for one person, and the grinding of a set of bearing soft belts requires 20-22 hours for one person. The Stu robot grinding and chamfering equipment can achieve tooth chamfering 2 Hours/piece, soft belt polishing 3 hours/set!

Our technological breakthroughs

1. Use high-precision 3D line scanning vision to collect data and automatically output the trajectory.

2. The automatic tool changing function is adopted to automatically switch the corresponding tools according to the processing technology requirements.

3. According to the input workpiece parameters, it can automatically identify and judge whether the current tool and the driving gear match, and has automatic logical judgment function.

4. Chamfer grinding process control function: different processing parameters can be set at different track positions; automatic switching function: integrated workstation.

5. Multi-functional rotating platform. The turntable adopts multi-drive mode and is compatible with chamfering and grinding of toothed or toothless workpieces.

6. The grinding position adopts active recognition mode, and the grinding trajectory is automatically generated, and it has the function of automatic extraction and correction.

The Stu robot grinding and chamfering equipment realizes chamfering and grinding of the upper and lower sides of the workpiece at one station, greatly reducing the number of turnovers of the workpiece, reducing the workload of traditional manual labor, and achieving chamfering and grinding of large-scale rotary supports with high quality and efficiency. work and has great application significance.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.