-

-

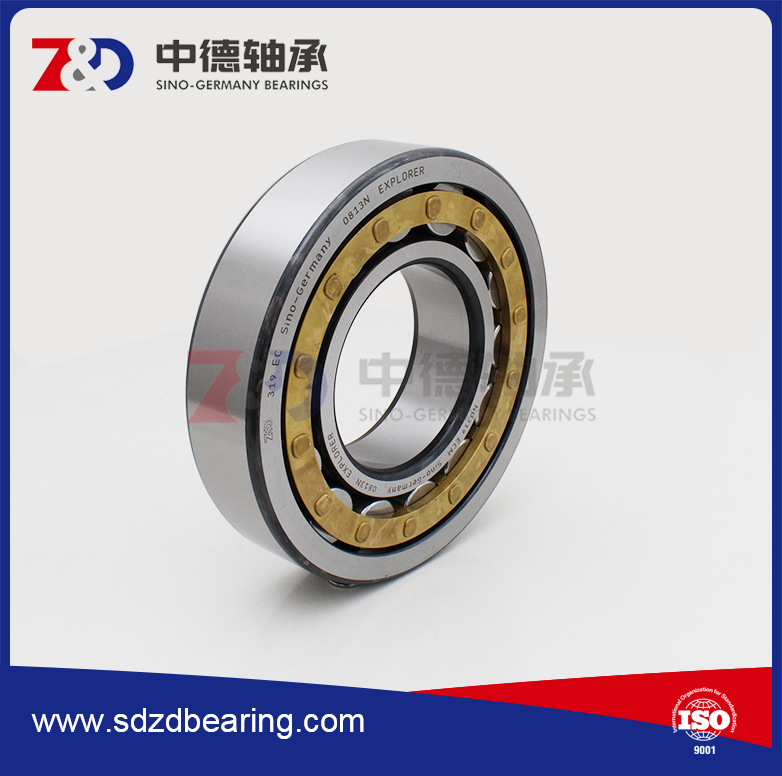

Product name: NU1007

-

-

Price: ASK

-

-

Post date: 2019-09-26

-

-

Stock Quantity: 1000

-

Cylindrical roller bearing type belongs to the separation bearing, installation and removal is very convenient, cylindrical roller bearing can withstand the big radial direction load and is suitable for use in high-speed operation situation, raceway and rolling body is in the shape of geometry has higher bearing capacity.Guard and roller end face a new type of structure design, not only improve the axial bearing capacity of the bearing, at the same time improve the roller end face and guard contact area of the lubrication conditions, improve the use of bearing performance.

The internal structure of cylindrical roller bearing by roller are arranged 90 ° vertically cross each other, with intervals between roller holder or isolation, to prevent mutual friction between roller tilt or roller, effectively prevent the rotation torque increases.

Cylindrical roller and race for line contact bearing.Load capacity is big, mainly bear radial load.Roller and ring guard friction small, suitable for high speed rotation.

May according to the ring presence of guard, NU, NJ, NUP, N, NF, such as single row cylindrical roller bearings, double row cylindrical roller bearing and NNU, NN and other.The bearing inner ring and outer ring is separable structure.

Cylindrical roller bearing characteristics

1. The roller and raceway for the line contact or offline contact, radial bearing capacity big, apply to under heavy load and impact load.

2. The friction coefficient is small, suitable for high speed, the limit speed close to the deep groove ball bearings.

3. The N type and NU type axial movement, can adapt to shaft caused by thermal expansion or installation error and shell the change of relative position, can be used for free end bearing.

4. On the shaft or hole of the processing and the demand is higher, bearing outer axis relative deflection after installation to be kept under strict control, so as not to cause contact stress concentration.

5. The inner ring or outer ring separable, easy to install and disassemble.

About Shandong Sino-Germany Precision Bearing Manufacturing Co.,Ltd

Shandong Sino-Germany Precision Bearing Manufacturing Co.,Ltd is committed to the research and manufacturing of general high and new technological products. With 20 years’ research and development production experiences, it has professional researchers and advanced equipments, including 36 sets of import equipments and 126 sets of major high precision processing equipments.

Sino-Germany Precision Bearing has invested the modernized workshops, containing a world-class advanced heat treatment workshop, two mechanical processing workshops, and modernized constant temperature dust free assembly workshop, provincial metrology inspection centre, heat treatment lab, modernized management storehouse etc. Relying on domestic and oversea markets, the company has formed good circulation of a generation of development, a generation of store, and a generation of production in product development and manufacturing. At the same time, with the enhancement of the investment of development and research, the company has created its own brand and strived to increase the export of high technological and high value added products. Moreover, it has achieved excellent record with the annual production scale of 3 million sets, achieving the profits tax of RMB 15 million.

Sino-Germany Precision Bearing professional production in high precision of spherical roll child bearing, cylindrical roll child bearing,, and spherical roll child bearing,such as CC,E type (SKF structure) and E1 (FAG structure), cylindrical roll child bearing EM and ECM. our equipped with world most advanced of Austria love Association forest heat treatment equipment, advanced of production process and the NC machine, these are for products of quality provides has guarantees. Their main brands is Z&D,and they can also offer service neutral or OEM.

More information, http://www.sgbearing.com