NSK welcomes visitors to the 48th Pulp & Paper International Exhibition

Published on:08 Oct,2015

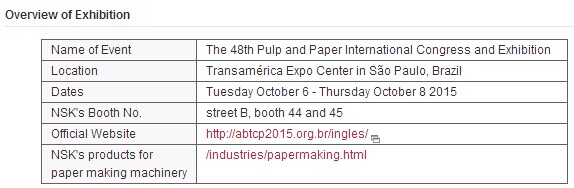

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it will exhibit at the 48th Pulp and Paper International Congress and Exhibition, promoted by ABTCP Brazilian Pulp and Paper Technical Association, from October 6th to 8th in São Paulo.

NSK will exhibit its' line of products like spherical roller bearings developed specially for equipment of this segment. The company will also present the AIP (Asset Improvement Program) that shows to the customer the benefits of using NSK bearings in their plants focus on cost reduction and productivity increase.

“To apply the AIP without any cost for the customer is a global success because it demonstrates how much can be saved on the bearing´s durability, acquiring an increase in performance, reducing costs, and elevating their productivity”, says Luiz Granjo, Strategic Planning & Marketing Manager of NSK Brazil. Companies of several segments obtained more than Brazilian Real 6 million in (US$ 1.5 million) cost reductions with the application of AIP. It is estimated that in 2015 the result will be more than Brazilian Real 9 million (US$ 2. 3 million).

Major Exhibits

High-Performance Precision Ball Screw (Japan premiere)

NSKHPS™ High Performance Standard Bearings for Industrial Machinery

NSK successfully developed the NSKHPS series of spherical roller bearings, which provide a longer service life and higher limiting speeds, by employing leading-edge materials and technology in combination with years of cultivated experience and technical know-how.

Features:

Bearing life increased by twofold (increased dynamic load rating by 25 %).

Limiting speed increased by 20 %.

TL Series Spherical Roller Bearings

Provide superior resistance to inner ring fractures, which is ideal for papermaking machinery operating under high-temperature conditions. The tough, long-life, TL series of bearings help boost productivity and lower costs.

Features:

Adopting NSK's proprietary steel grade (new specification bearing material) and a special case hardening and heat treatment process, resistance against inner ring fracturing has been dramatically improved.

Raceway surface hardness has been increased for longer life performance.

Dimensional stability under high temperature (200°C) operating conditions.

Molded-Oil™ Bearings

Molded-Oil bearings are lubricated with oil-impregnated solid material, which is contained within the bearing. Oil slowly seeping from this solid lubricant material provides ample lubrication to the bearing for extended periods.

Features:

Designed to prevent water and other liquids from washing out the lubricating oil while preventing dust and other contaminants from getting inside the bearing.

Low-torque performance, which is achieved by packing the bearing with oil-impregnated solid material after bearing surfaces have undergone a special surface treatment.

Protect the working environment by eliminating stray oil mist or leakage.

High-speed capability enabled through optimal composition of the solid lubricant material and methods used for the molding process.

Triple Ring Bearings

A uniquely structured, highly precise, long life, anti-creep bearing that also facilitates easy of handling and mounting.

Features:

High load capacity design.

Vacuum melted, carburized steel for long life performance.

High precision.

Optimal inner ring design for improved lubrication.

Lubrication hole and groove provided on inner and outer rings.

CA Series Spherical Roller Bearings

The CA series features a machined cage; offers superior radial load capacity and alignment; and provides high load capacity and excellent strength. This product line includes the high-precision products shown on page 55.

Features:

High load capacity.

High-strength machined brass cage.

About NSK

As Japan's first bearings manufacturer, NSK has a history spanning nearly a century. As one of the world's leading bearings manufacturers, NSK contributes to industrial development globally by quickly and accurately meeting the diverse needs of customers around the world.

Based on the theme of “Motion & Control” as the cornerstone of its business operations, the company develops and provides steering and other automotive parts as well as precision and parts products in addition to bearings.

NSK is a global enterprise with 214 facilities in 30 countries that serve a diverse range of industrial customers with a wide range of precision components in addition to bearings. NSK operates 65 plants across the globe, and among these, two-thirds are located outside of Japan. 66% of NSK's revenues were generated outside of Japan in FY2014.

NSK built NSK Brazil as its first overseas plant in Suzano City, just on the outskirts of San Paulo.

NSK Brazil manufactures industrial machinery bearings used mainly for electric appliances. The plant has been contributing to the local economy for decades. Today, NSK in Brazil is operating 5 sales offices, 1 R&D center, and 1 plant, and is supplying high quality products to many customers in Brazil.

NSK Brazil is one the most advanced business units in terms of promoting localization of production. At the Suzano plant, NSK has enhanced domestic procurement and has been expanding its production capacity since its establishment. NSK intends to supply products that meet the needs of customers by fully utilizing its extensive know-how and the highly skilled people who have been developed through decades of business operations in the region.