Bosch develops SiC microchips to boost e-mobility

Published on:18 Nov,2019

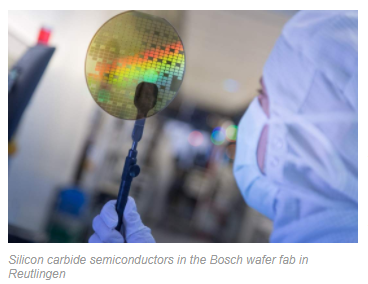

Bosch manufactures the new generation of semiconductor chips at its Reutlingen plant, 25 miles south of Stuttgart.

German multinational engineering and technology company Bosch has recently developed new microchips made of silicon carbide (SiC) to help electromobility make a great leap forward.

Compared to the silicon chips used to date, SiC semiconductors have better electrical conductivity, the company said in a release.

This enables higher switching frequencies while also ensuring that much less energy is dissipated in the form of heat.

Bosch manufactures the new generation of semiconductor chips at its Reutlingen plant, 25 miles south of Stuttgart.

According to the company, semiconductors made of silicon carbide set new standards for switching speed, heat loss, and size.

“Silicon carbide semiconductors bring more power to electric motors. For motorists, this means a 6 percent increase in range,” said Harald Kroeger, member of the Bosch board of management.

It all begins with additional carbon atoms, which are introduced into the crystalline structure of the ultra-pure silicon used to manufacture semiconductors. The chemical bond created in this way turns the semiconductor chips into real powerhouses. Especially for applications in electric and hybrid vehicles, this means many advantages.

In power electronics, they ensure that 50 percent less energy is lost in the form of heat. This saving translates into more efficient power electronics and more energy for the electric motor and therefore for the battery range. Motorists can drive 6 percent further on a single battery charge.

Alternatively, car manufacturers can make the battery smaller for a given range. This reduces the cost of an electric car’s most expensive component, which in turn reduces the vehicle’s price.