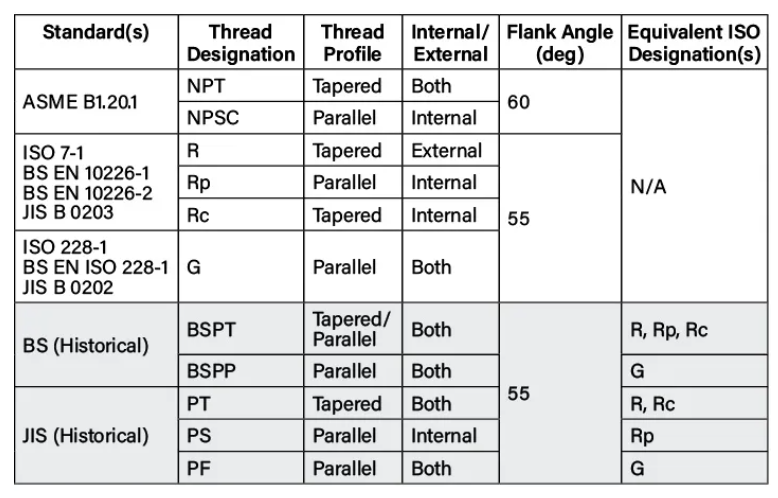

Regarding American National Standard pipe, ASME B1.20.1 covers the following series: NPT, NPSC, NPTR, NPSM and NPSL. All of these thread series specify threads with a 60° angle between the flanks (see Figure 2). Among these, NPT is the most common and indicates a tapered thread for both internal and external threads. NPT threads are designed to be fitted together wrench-tight and require a sealant for a pressure-tight seal (Ref. 10). NPSC threads are parallel internal threads, which are designed to be fitted wrench-tight with an external NPT thread. As with NPT/NPT connections, a sealant is required for a pressure-tight seal (Ref. 9). NPTR (tapered threads for railing joints), NPSM (straight threads for mechanical joints), and NPSL (straight threads for mechanical joints with locknuts) have the same thread profile dimensions as NPT or NPSC, but have certain modifications for specific applications (Ref. 10). A separate standard, ASME B1.20.3, covers inch Dryseal pipe threads, which can create a pressure-tight connection without a sealant. The series covered by this standard are NPTF, PTF-SAE SHORT, NPSF and NPSI (Ref. 11). ISO, British Standard, and JIS pipe threads are commonly used outside of the US. These thread standards all specify a 55° flank angle and specify two families of pipe threads: those for pressure-tight joints and those for non-pressure-tight joints. Pipe threads where pressure-tight joints are made on the threads are defined in ISO 7-1, BS EN 10226-1, BS EN 10226-2, and JIS B 0203. These standards all define identical thread series which are designated with R for external tapered thread, Rp for internal parallel thread, and Rc for internal tapered thread. For these connections, thread sealant is required to achieve a pressure-tight seal (Refs. 1, 2, 5, 7). ISO 228-1, BS EN ISO 228-1, and JIS B 0202 define pipe threads where pressure-tight joints are NOT made on the threads. These standards define identical thread series which are parallel for both internal and external threads and are designated with G. If a pressure-tight joint is required with these threads, then an external seal or gasket is required (Refs. 3, 6, 8). With the latest standards listed in the previous paragraph, BS and JIS have adopted the same symbols as the ISO standard (namely R, Rp, Rc and G), but the historical symbols previously specified in the standards are still frequently used. In the British Standard, the historical symbols are BSPT and BSPP (Ref. 4). In the Japanese Industrial Standard, the historical symbols are PT, PS and PF (Refs. 7, 8). The characteristics of these series are shown in Table 1, which also defines the equivalent ISO thread series for each.

To begin to address the confusion regarding pipe threads, it is helpful to take a step back and investigate some of the reasons for this confusion, some of which are listed below: Different designations use the same nominal sizes (e.g., 1/2), even though they may have different thread profiles, dimensions, and tolerances. Some of the designations have similar letters in the nomenclature but are not necessarily equivalent (NPT, BSPT, PT). Certain historical designations are still extensively used, such as BSPP and BSPT. Certain sizes of different thread standards can be screwed together, but not in a leak-proof manner. This means that physically fitting two threads together does not guarantee proper fit and leak prevention. Different thread types require different sealing methods (sealant, O-ring, etc.). Within each standard, the relationships between thread series are clear. Problems mainly arise from attempts to combine threads from different standards. The next section will address some of these problems and clarify which thread series are equivalent and compatible, and which are not.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.