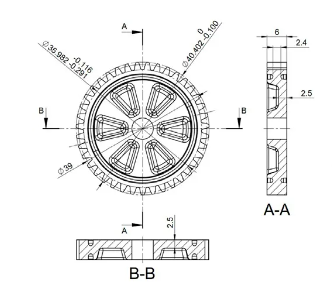

The test gears were fabricated via injection molding using a single-cavity mold. Molding operations were conducted on an Engel Victory 50 injection molding machine (Engel Austria GmbH, Austria). A three-plate mold configuration incorporating a hot-runner system and a centrally positioned pin-point gate with a 1.3 mm diameter was employed. Gear geometry conformed to the specifications outlined in VDI 2736, Part 4, Table 1, corresponding to Size 1 geometry (Ref. 9). The gear body was engineered with a wavy structural design, maintaining a consistent wall thickness of 2.5 mm (Figure 1). A symmetric groove was integrated at the interface between the gear body and tooth region to promote uniform material flow and complete cavity filling during the molding process.

The gears were manufactured from seven commercially available thermoplastic compounds widely utilized in gear production. The injection mold was engineered with an interchangeable cavity system, enabling the use of multiple cavity inserts tailored to accommodate the differential shrinkage behavior associated with the various tested materials. This strategy ensured that all gear specimens were produced to a consistent quality standard, thereby minimizing the influence of dimensional and geometric variations on NVH performance. To maintain commercial confidentiality, only the chemical compositions of the employed materials are disclosed: Polyoxamethylene (homopolymer)—POM Polyamide 66—PA66 Polyamide 6 + 15% glass fibers—PA6+15%GF Polyphthalamide + 30% glass fibers—PPA+30%GF Polyamide 66 + 30% glass fibers—PA66+30%GF Polyoxymethylene + 10% aramid fibers—POM+10%AF As a reference for comparative analysis, three sets of steel gears were fabricated from heat-treated 42CrMo4 alloy, maintaining identical gear geometry as specified in Table 1.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.