The gear pairs were evaluated within an enclosed acoustic chamber integrated into the gear test rig, effectively isolating the test specimens from external acoustic interference. This setup ensured that only the noise generated by the meshing gear pair was captured, eliminating the influence of extraneous sound sources. Throughout all experiments, rotational speed, applied torque, and gear temperature were rigorously controlled (Figure 4). Given the sensitivity of NVH performance to operating conditions, each gear pair was tested at two discrete torque levels, with three corresponding rotational speeds per torque level, to assess the influence of both parameters. Gear temperature was actively regulated and maintained at 80°C, measured directly in the tooth engagement zone. The complete matrix of test loads is detailed in Table 3. Testing was conducted under both dry and, for selected combinations, grease-lubricated conditions. For each material pairing, three independent test repetitions were performed, with a new gear pair employed in each instance to eliminate the effects of wear. All gear sets operated at a fixed theoretical center distance of 38.45 mm, established using a high-precision positioning mechanism with an accuracy of ±0.01 mm.

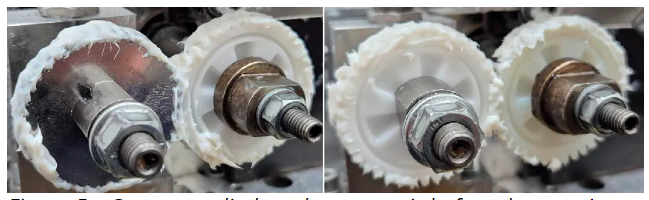

Seven distinct polymer material combinations, selected from commercially available grades commonly utilized in gear applications, were evaluated in this study. For comparative benchmarking, a steel gear pair of identical geometry was also tested. The evaluated material pairings are as follows: Steel–Steel Steel–POM (run in dry and grease-lubricated conditions) POM–PPA+30%GF PA66–PPA+30%GF POM–PA66 (run in dry and grease-lubricated conditions) PA6+15%G–POM+10%AF POM–PA66+30%GF One key advantage of plastic gears is their ability to operate in dry conditions without external lubrication. However, many gearboxes with plastic gears still use grease, as it typically improves efficiency and reduces wear. To reflect common practical applications, most of the tested material combinations were evaluated under dry conditions, except for the Steel–POM and POM–PA66 gear pairs, which were tested in both dry and grease-lubricated environments. The lubricant used was a grease formulated from synthetic hydrocarbon base oil thickened with a barium complex soap. The kinematic viscosity of the base oil at 80°C was measured at 10.3 cSt. Prior to testing, the grease was manually applied to the gear teeth, ensuring complete coverage of the meshing surfaces on both gears (Figure 5). No additional grease was supplied during the test runs.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.