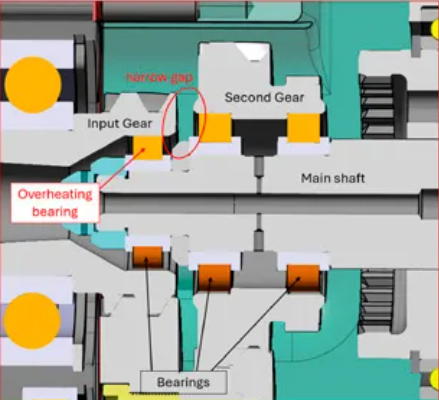

Developing an analysis workflow for gearbox lubrication involves several critical steps that must be meticulously executed to ensure accurate and reliable results. The process begins with CAD preparation in Dassault Systèmes 3DExperience using CATIA applications. CAD Preparation If the geometry is not native to the 3DExperience platform, it needs to be imported, with STEP files being the most robust option. Once imported, the assembly must be filtered to retain only the relevant parts for the lubrication simulation. Bolts, rivets, and parts not in contact with the lubricant should be removed. Unnecessary features, such as bolt and rivet holes, must be defeatured to avoid small vertices, unsuitable lattice sizes, and poor resolution. The casing, typically composed of several parts, should be merged to create a single watertight envelope. This is crucial for XFlow’s lattice generation to accurately recognize fluid domain boundaries. To expedite the CFD scenario definition, it is recommended to group parts rotating at the same speed into the same sub-assembly, allowing the equation of motion to be set once. Modeling bearings poses a challenge due to their many separate moving parts, such as balls or rollers. A simple donut shape would prevent any lubricant movement across the bearings. Bearings could be considered as porous zones, but this approach requires calibration and experimental data or a specific analysis. Given XFlow’s proficiency in handling rotating parts, we decided to model each ball and roller within the main bearings. The motion of ball or roller is complex, as each rotates around its own center. To simplify the setup, we applied a uniform motion equation to all balls or rollers, averaging the velocities of the bearing’s external (Ve) and internal case ((Vi)) : (Ve+Vi)/2. Once the relevant parts are selected and defeatured, the assembly is reorganized, and the casing is made watertight. The parts are then ready for meshing. Discretization Having a unified shared mesh is crucial for accurate data transfer between the CFD and heat transfer analysis. In the CFD analysis, discretization involves representing a continuous solid in a tessellated environment. Spherical and cylindrical shapes must be finely discretized to ensure realistic interactions with the fluid. A coarse mesh would create a rough interface, leading to excessive interaction with the fluid. For the heat transfer analysis, meshing serves to represent continuous parts within an element-based solver. A mesh that is too fine demands more computing power, primarily RAM, and increases runtime. Additionally, it requires longer data processing to map the heat transfer coefficient accurately. Meshing solid parts involves discretizing them for the conduction equation, balancing the need for detail with computational efficiency. The equation of conduction, also known as Fourier’s law of heat conduction, describes the rate at which heat energy is transferred through a material due to a temperature gradient.

Since the equation is linear, the element order can also be linear. We mostly utilized tetrahedral linear elements, applying an absolute sag criterion to refine areas with small radii to capture finer details. The bearings were meshed with linear hexahedral elements. The specific mesh size was determined to balance accuracy and computational efficiency. In total, we had nearly one million elements. This mesh information is then transferred to XFlow to construct the CFD analysis scenario.

Next Battle-Tested Tech for Aerospace and Defense Operations

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.