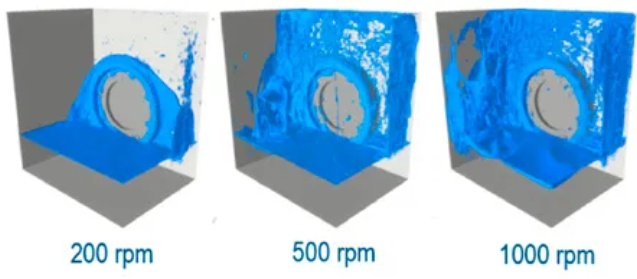

Correlation of the developed workflow is an essential step to ensure its accuracy and reliability. The process involves several stages, beginning with the visual comparison of lubricant splashing. Slow-motion videos recorded using high-speed cameras are matched with animations generated from the CFD analysis. This visual correlation provides a qualitative assessment of the simulation’s accuracy in replicating real-world conditions. The second stage involves measuring the churning loss of the gearbox. The total torque loss on the test bench includes bearing losses, gear friction, seal friction, and churning losses. Accurate evaluation of the other three components is necessary to isolate and compare the churning losses with the torque measured in the CFD analysis. This quantitative comparison validates the simulation’s accuracy in predicting torque losses due to lubricant movement. The solver has been validated based on comparison with experimental data (Ref. 4). Two different scenarios, one single gear and two engaged gears, are tested experimentally and compared with numerical prediction. Figure 13 shows the comparison of experimental versus numerical churning losses estimation using XFlow 2022 solver. It shows a good correlation at various speeds.

Temperature measurements represent the third stage of validation. Temperature data collected on the test bench are compared to the simulated overheating conditions. Ensuring that the CAD model used in simulations accurately represents the prototype on the test bench is critical for this comparison. The same lubricant temperature, applied torque, and rotational speeds must be represented in both physical and simulated environments. In our project with the gearbox manufacturer, the prototype on the test bench was an earlier version of the design. The test bench lacked a sensor capable of measuring torque losses, which would have allowed us to extract the total churning loss. Additionally, a few temperature labels were installed on shafts that had been altered between the prototype and the CAD model. These labels provided a range of temperatures reached or indicated if the maximum temperature had been exceeded. The company’s team acknowledged that the lubrication animations we provided were comparable to what they had observed through the casing window of their test bench. Our predictive model was able to reproduce the overhearing problem, estimating a temperature of 176°C, above the limit that the bearing can endure without damage. In many companies, the test team and the CFD analysts work separately. The test team often does not know what information the CFD team needs to correlate their models. Consequently, test reports are frequently incomplete and lack the crucial data required to validate the workflow. Greater collaboration between the test and CFD teams is necessary to build identical prototypes for both the test bench and the simulations. Strategic placement of thermocouples is essential for comparing predicted and actual temperatures, and churning loss measurements should be taken to gain confidence in the accuracy of the simulations.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.