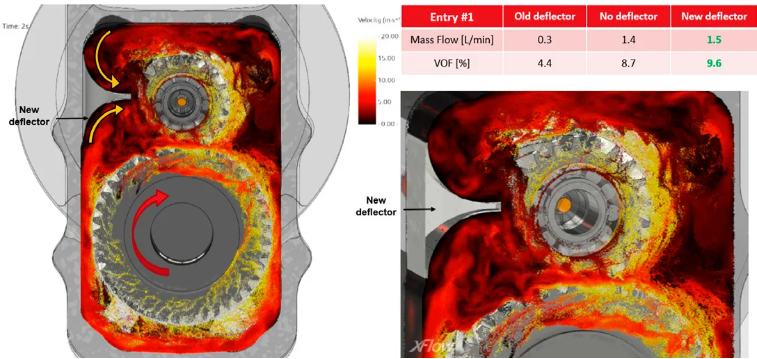

The developed workflow offers numerous advantages, significantly enhancing the efficiency and accuracy of gearbox lubrication analysis. One of the primary benefits is the quick setup and analysis time. Engineers can prepare an analysis in just a few hours, with post-processing and animation generation automated using scripts. This efficiency allows for rapid iteration and comparison of design variations, enabling engineers to make informed decisions quickly. Having a numerical model leads to a powerful virtual lab, allowing for the testing of multiple conditions and scenarios without the need for physical prototypes. Engineers can rapidly iterate designs, run designs of experiments (DOE), and find optimized solutions. By adjusting parameters such as gravity equations and initial lubricant levels, various operating conditions can be simulated, including road slopes, acceleration, braking and turning events. Different weather conditions can be modeled by altering lubricant properties, providing a comprehensive understanding of gearbox performance under a wide range of scenarios. This capability enables the exploration of “what if” scenarios that would be impractical or costly to test experimentally. For instance, simulations can assess the gearbox performance without lubricant, test alternative lubricants, or evaluate the impact of component failures. This flexibility is invaluable for manufacturers, as it enhances their knowledge and expertise, leading to continuous improvement in product design and performance. In the context of our project, the virtual lab allowed for testing several deflector designs intended to guide more lubricant towards the overheating bearing. The initial deflector design created local lubricant recirculation, which was impossible to detect experimentally. Simulations provided critical insights, revealing the inefficiencies of the initial design and guiding the development of optimized deflector configurations. The improved deflector design, shown in Figure 14, was based on the animations of the lubricant movement. It uses double slopes directing both the flow coming up on the left side wall, and the flow moving counterclockwise around the input gear.

No recirculation pattern, nor low velocity areas were observed. Figure 14 shows important lubricant motion near the overheating bearing. The table presents the comparison of flow quantity accessing the overheating bearing, indicating better performance. The improvements compared to without the deflector were not significant, but it shows that virtual testing allows us to quickly evaluate and compare designs.

Quantitative metrics such as churning loss, volume flow across surfaces, and temperatures allow for the ranking of different designs and sensitivity studies. This ranking helps design teams identify the most effective configurations and better understand the parameters that most significantly affect lubrication performance. By providing detailed insights into the lubricant distribution and heat transfer characteristics within the gearbox, the virtual model enables the development of more efficient and reliable designs.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.