Shooting for the STARS

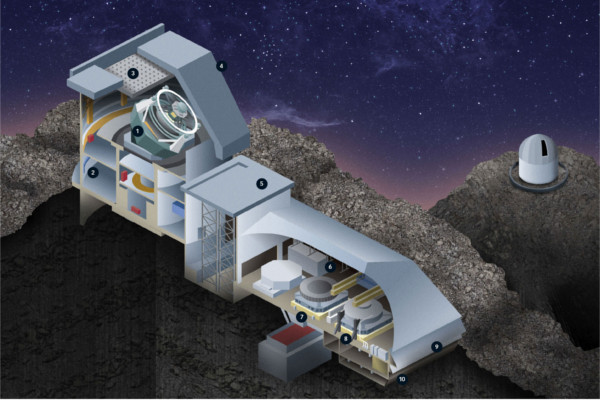

LSST main parts

1. 350-tonne telescope

2. 16-metre-long tele-scope pier

3. 11-metre-wide wind/light screen

4. 30-metre-high dome

5. 27-metre-high vertical platform lift

6. camera clean room

7. 75-tonne M1M3 tele-scope cell

8. coating chamber

9. control room

10. machine shop

The fundamental design concept is straightforward: to provide a frequent deep surveying of the whole visible sky over a 10-year period, creating the largest astronomical catalogue of images and data in existence. Spanish engineering company Empresarios Agrupados (EA), which has a proven track record in large telescope facilities, particularly the GranTeCan telescope on La Palma in the Canary Islands, was commissioned to develop and supply the detail design and engineering and to manage manufacturing, construction, erection and testing of the LSST mount assembly. The telescope is being manufactured at the Asturfeito steel facility in Asturias, Spain.

Alfredo Orden, head of the components section in the EA mechanical department, leads a team of 20 engineers specialized in mechanical engineering, control systems, electrical engineering, construction and layout. “There are a number of challenges that we have faced with the design of the LSST – supporting an 8.4-metre-diameter mirror assembly and a three-metre digital sensor, designing a structure that will withstand the frequent seismic shocks in this part of Chile and making sure that the whole assembly moves with pinpoint accuracy and has minimal downtime and maintenance requirements,” he says. “All these factors require the highest standard of engineering design.”

But Orden seems to take the scale and complexity of the project in stride. “Engineering is engineering,” he says. “We solve engineering problems. The biggest challenges are how to be competitive. The size and scope of any project is decided by the limits of the engineer’s imagination and intelligence. Our approach here is to maintain a working atmosphere with a constant dynamic interchange of ideas. The reliability and precision of the LSST components are critical to its successful functioning. It’s our job to make sure that all the design elements – procurement, construction, installation and seamless functioning of all mechanical and electrical systems – are perfect.”

LSST main parts

1. 350-tonne telescope

2. 16-metre-long tele-scope pier

3. 11-metre-wide wind/light screen

4. 30-metre-high dome

5. 27-metre-high vertical platform lift

6. camera clean room

7. 75-tonne M1M3 tele-scope cell

8. coating chamber

9. control room

10. machine shop

The fundamental design concept is straightforward: to provide a frequent deep surveying of the whole visible sky over a 10-year period, creating the largest astronomical catalogue of images and data in existence. Spanish engineering company Empresarios Agrupados (EA), which has a proven track record in large telescope facilities, particularly the GranTeCan telescope on La Palma in the Canary Islands, was commissioned to develop and supply the detail design and engineering and to manage manufacturing, construction, erection and testing of the LSST mount assembly. The telescope is being manufactured at the Asturfeito steel facility in Asturias, Spain.

Alfredo Orden, head of the components section in the EA mechanical department, leads a team of 20 engineers specialized in mechanical engineering, control systems, electrical engineering, construction and layout. “There are a number of challenges that we have faced with the design of the LSST – supporting an 8.4-metre-diameter mirror assembly and a three-metre digital sensor, designing a structure that will withstand the frequent seismic shocks in this part of Chile and making sure that the whole assembly moves with pinpoint accuracy and has minimal downtime and maintenance requirements,” he says. “All these factors require the highest standard of engineering design.”

But Orden seems to take the scale and complexity of the project in stride. “Engineering is engineering,” he says. “We solve engineering problems. The biggest challenges are how to be competitive. The size and scope of any project is decided by the limits of the engineer’s imagination and intelligence. Our approach here is to maintain a working atmosphere with a constant dynamic interchange of ideas. The reliability and precision of the LSST components are critical to its successful functioning. It’s our job to make sure that all the design elements – procurement, construction, installation and seamless functioning of all mechanical and electrical systems – are perfect.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.