Benefits of Hybrid Bearings in severe conditions

The main result of the correl-ation between the measurements and the numerical simulation (using the fatigue-based model [6] and combined fatigue-wear model [5]) of the surface-distress area for hybrid and all-steel contacts under the above-mentioned conditions is shown in fig. 2. One can easily observe a gradual accumulation of surface distress in time for the all-steel contact, while the hybrid one exhibits practically no surface distress. One can also see that the results of the combined surface distress/wear model with wear rates typical for hybrid contacts (blue curves) agree with the experimental data slightly better than the results of the model assuming no wear (black curves).

The main result of the correl-ation between the measurements and the numerical simulation (using the fatigue-based model [6] and combined fatigue-wear model [5]) of the surface-distress area for hybrid and all-steel contacts under the above-mentioned conditions is shown in fig. 2. One can easily observe a gradual accumulation of surface distress in time for the all-steel contact, while the hybrid one exhibits practically no surface distress. One can also see that the results of the combined surface distress/wear model with wear rates typical for hybrid contacts (blue curves) agree with the experimental data slightly better than the results of the model assuming no wear (black curves).

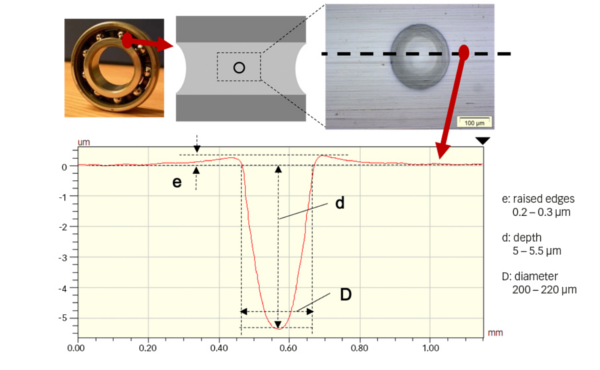

For more clarification and quantification, a direct comparison of performance was studied through experiments and modelling of artificial dents on the steel raceway when overrolled by steel or Si3N4 rolling elements [9]. Such dents were created on the inner ring of all-steel and hybrid deep groove ball bearings (fig. 3). The -bearings were then tested under equal operating conditions. The example shown in fig. 4 was for an operating condition of very good lubrication (full film) and medium contact pressure. Considering the Young’s modulus of the Si3N4 balls, this means that the hybrid contact is operating with a slightly higher nominal contact pressure (e.g., table 1). Regular interruption of the tests for inspection and measurements showed a noticeable difference between the all-steel and hybrid bearings in the surface aspect and changes of the dent raised edges (fig. 4a).

For more clarification and quantification, a direct comparison of performance was studied through experiments and modelling of artificial dents on the steel raceway when overrolled by steel or Si3N4 rolling elements [9]. Such dents were created on the inner ring of all-steel and hybrid deep groove ball bearings (fig. 3). The -bearings were then tested under equal operating conditions. The example shown in fig. 4 was for an operating condition of very good lubrication (full film) and medium contact pressure. Considering the Young’s modulus of the Si3N4 balls, this means that the hybrid contact is operating with a slightly higher nominal contact pressure (e.g., table 1). Regular interruption of the tests for inspection and measurements showed a noticeable difference between the all-steel and hybrid bearings in the surface aspect and changes of the dent raised edges (fig. 4a).

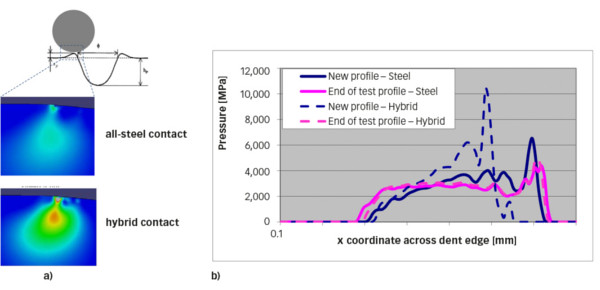

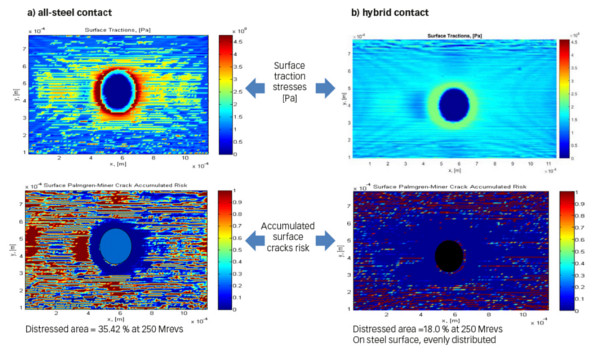

The all-steel bearing showed limited plastic deformation and dent shape change of the raised dent edges (fig. 4b). This limited reconforming maintains a certain level of local pressure distribution when the raised edge of the dent is overrolled (as shown in fig. 5b). In addition, the surfaces showed clear superficial damage. On the leading edges of the dent (fig. 4d), where film collapse is expected, two mechanisms were observed: some superficial adhesive wear and superficial plastic deformation by asperities micro-denting as the steel balls’ surface is also roughened when overrolling the dent. On the trailing edge of the dent, where higher stress concentration is expected, the all-steel bearing showed superficial plastic deformation by asperities, micro-denting the raised dent edges. With running time the material is deformed and pushed into the dent (fig. 4e), and a small surface crack is initiated and slowly propagates upon further operation. Surface distress modelling [6, 7] indicates a local ring of high surface traction stresses and distress (fig. 6a) and crack initiation risk corresponding to the specific location observed in the tests (fig. 4b and fig. 4e).

At an early stage of operation the hybrid bearing developed larger and flatter dent edges (fig. 4a and fig. 4c). Mild wear erasing the finishing marks and maintaining a very smooth surface (fig. 4f) was observed on the leading edge from the very beginning. The Si3N4 ball surface also remained in good condition and maintained its initial roughness. The earlier shakedown (plastic stabilization) with material pushed into the dent was explained with elastoplastic finite element simulation (fig. 5a) showing higher stress and therefore higher local deformation for the hybrid contact. With further running time, mild wear (fig. 4g) was also observed on the trailing edge. This fast mild wear reconforming the dent edges and changing their slopes (fig. 4a) stabilizes over running time, and the dent shape no longer evolves. The pressures are sufficiently reduced to stop the mild wear mechanism.

The all-steel bearing showed limited plastic deformation and dent shape change of the raised dent edges (fig. 4b). This limited reconforming maintains a certain level of local pressure distribution when the raised edge of the dent is overrolled (as shown in fig. 5b). In addition, the surfaces showed clear superficial damage. On the leading edges of the dent (fig. 4d), where film collapse is expected, two mechanisms were observed: some superficial adhesive wear and superficial plastic deformation by asperities micro-denting as the steel balls’ surface is also roughened when overrolling the dent. On the trailing edge of the dent, where higher stress concentration is expected, the all-steel bearing showed superficial plastic deformation by asperities, micro-denting the raised dent edges. With running time the material is deformed and pushed into the dent (fig. 4e), and a small surface crack is initiated and slowly propagates upon further operation. Surface distress modelling [6, 7] indicates a local ring of high surface traction stresses and distress (fig. 6a) and crack initiation risk corresponding to the specific location observed in the tests (fig. 4b and fig. 4e).

At an early stage of operation the hybrid bearing developed larger and flatter dent edges (fig. 4a and fig. 4c). Mild wear erasing the finishing marks and maintaining a very smooth surface (fig. 4f) was observed on the leading edge from the very beginning. The Si3N4 ball surface also remained in good condition and maintained its initial roughness. The earlier shakedown (plastic stabilization) with material pushed into the dent was explained with elastoplastic finite element simulation (fig. 5a) showing higher stress and therefore higher local deformation for the hybrid contact. With further running time, mild wear (fig. 4g) was also observed on the trailing edge. This fast mild wear reconforming the dent edges and changing their slopes (fig. 4a) stabilizes over running time, and the dent shape no longer evolves. The pressures are sufficiently reduced to stop the mild wear mechanism.

Although the local pressures were higher for the hybrid bearing to start with, the reconforming of the dent shape reduced the local pressure to a similar level as the all-steel bearing (fig. 5b) for this test condition. In addition to this reduction of local pressure, surface distress modelling [9, 10] indicated a reduction of pressure gradient at the dent edges. More importantly, and especially for the local dent edge thin lubricating film condition, surface distress modelling indicates lower surface traction stresses and lower fatigue accumulation or crack initiation risk (fig. 6b). This is due to the lower boundary friction-coefficient in the hybrid contact [6].

Although the local pressures were higher for the hybrid bearing to start with, the reconforming of the dent shape reduced the local pressure to a similar level as the all-steel bearing (fig. 5b) for this test condition. In addition to this reduction of local pressure, surface distress modelling [9, 10] indicated a reduction of pressure gradient at the dent edges. More importantly, and especially for the local dent edge thin lubricating film condition, surface distress modelling indicates lower surface traction stresses and lower fatigue accumulation or crack initiation risk (fig. 6b). This is due to the lower boundary friction-coefficient in the hybrid contact [6].

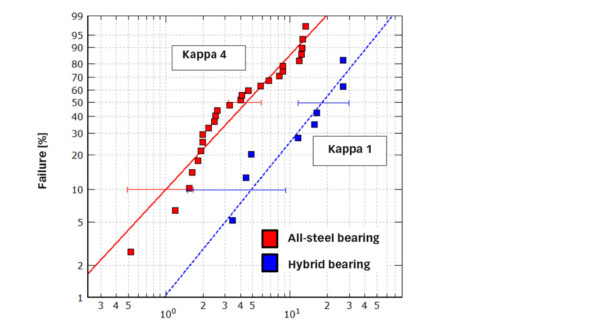

A dent life was determined under equal load conditions for all-steel and hybrid bearings (fig. 3). The hybrid bearing operating at higher maximum contact pressure and thinner film condition still gave a better dent life than the all-steel bearing operating at lower max-imum contact pressure in full film (fig. 7).

A dent life was determined under equal load conditions for all-steel and hybrid bearings (fig. 3). The hybrid bearing operating at higher maximum contact pressure and thinner film condition still gave a better dent life than the all-steel bearing operating at lower max-imum contact pressure in full film (fig. 7).

These findings can be seen as counterintuitive, but they illustrate the benefits of hybrid bearings when poor lubrication and surface asperities and frictional stresses are experienced, whether they are from denting or general poor lubrication. The presented mechanisms will compensate for eventual deeper dent created in the hybrid contact during particle entrapment and -overrolling that have been reported for pure rolling conditions [11]. These bene-fits greatly balance the higher contact pressure experienced in hybrid contacts over a certain range of loading conditions. However, for rare cases of application at very high contact pressures this positive balance may be jeopardized or reduced.

Summary

Hybrid bearings are much less prone to surface distress than all-steel ones due to the reduced boundary friction and favourable roughness topography of bearing grade silicon nitride.

In a hybrid bearing, only the steel counterpart undergoes mild wear, while the ceramic component remains nearly unaltered.

In contaminated conditions, mild wear, plastic deformation and maintaining of smooth surfaces on the dent edges in the hybrid bearing contribute to reducing local stresses.

The good resistance to surface distress and boundary lubricated condition-related damage around the dent where the film collapses was shown to lead to longer dent life for hybrid bearings.

References

[1] Lewinschal, L., “Bearings for high speed operation”, SKF Evolution, No. 2 1994, pp. 22-26. http://evolution.skf.com/bearings-for-high-speed-operations

[2] Hultman, A., Weimarck, A. K., “Ceramics stand up to harsh realities”, SKF Evolution, No. 4 1998, pp. 25-26. http://evolution.skf.com/ceramics-stand-up-to-harsh-realities

[3] Gabelli, A., Kahlman, L., “Bearings that heal themselves”, SKF Evolution No. 3 1999, pp. 26-28.

http://evolution.skf.com/bearings-that-heal-themselves-2

[4] Morales Espejel, G. E., Hauleitner, R., Wallin, H. H., “Pure refrigerant lubrication technology in oil-free centrifugal compressors”, SKF Evolution, No. 1 2017, pp. 26-30. http://evolution.skf.com/pure-refrigerant-lubrication-technology-in-oil-free-centrifugal-compressors

[5] Morales-Espejel, G.E., and Brizmer, V. (2011), “Micropitting Modelling in Rolling-Sliding Contacts: Application to Rolling Bearings”, Tribol. Trans., 54(4), pp. 625-643.

[6] Brizmer, V., Gabelli, A., Vieillard, C., and Morales-Espejel, G.E. (2015), “An Experimental and Theoretical Study of Hybrid Bearing Micropitting Performance under Reduced Lubrication”, Tribology Transactions, 58, pp. 829-835.

[7] Morales-Espejel, G.E., Gabelli, A., “The behaviour of indentation marks in rolling-sliding elastohydrodynamically lubricated contacts”, Tribology Transactions, 54, pp. 589-606, 2011.

[8] Morales-Espejel, G.E., Gabelli, A., “The progression of surface rolling contact fatigue damage of rolling bearing with artificial dents”, Tribology Transactions, 58, pp. 418-431, 2015.

[9] C. Vieillard, Y. Kadin, G.E. Morales-Espejel, A. Gabelli (2016), “An experimental and theoretical study of surface rolling contact fatigue damage progression in hybrid bearings with artificial dents”, Wear, pp. 364-365, pp. 211-223.

[10] Morales-Espejel, G. E., Brizmer, V., Stadler, K., “Understanding and preventing surface distress”, SKF Evolution, No 4 2011, pp. 26-31. http://evolution.skf.com/understanding-and-preventing-surface-distress

[11] V. Strubel, N. Fillot, F. Ville, J. Cavoret, P. Vergne, A. Mondelin, Y. Maheo., “Particle entrapment in hybrid lubricated point contacts”, Tribology Transactions 2016, VOL. 59, No. 4, pp. 768-779.

These findings can be seen as counterintuitive, but they illustrate the benefits of hybrid bearings when poor lubrication and surface asperities and frictional stresses are experienced, whether they are from denting or general poor lubrication. The presented mechanisms will compensate for eventual deeper dent created in the hybrid contact during particle entrapment and -overrolling that have been reported for pure rolling conditions [11]. These bene-fits greatly balance the higher contact pressure experienced in hybrid contacts over a certain range of loading conditions. However, for rare cases of application at very high contact pressures this positive balance may be jeopardized or reduced.

Summary

Hybrid bearings are much less prone to surface distress than all-steel ones due to the reduced boundary friction and favourable roughness topography of bearing grade silicon nitride.

In a hybrid bearing, only the steel counterpart undergoes mild wear, while the ceramic component remains nearly unaltered.

In contaminated conditions, mild wear, plastic deformation and maintaining of smooth surfaces on the dent edges in the hybrid bearing contribute to reducing local stresses.

The good resistance to surface distress and boundary lubricated condition-related damage around the dent where the film collapses was shown to lead to longer dent life for hybrid bearings.

References

[1] Lewinschal, L., “Bearings for high speed operation”, SKF Evolution, No. 2 1994, pp. 22-26. http://evolution.skf.com/bearings-for-high-speed-operations

[2] Hultman, A., Weimarck, A. K., “Ceramics stand up to harsh realities”, SKF Evolution, No. 4 1998, pp. 25-26. http://evolution.skf.com/ceramics-stand-up-to-harsh-realities

[3] Gabelli, A., Kahlman, L., “Bearings that heal themselves”, SKF Evolution No. 3 1999, pp. 26-28.

http://evolution.skf.com/bearings-that-heal-themselves-2

[4] Morales Espejel, G. E., Hauleitner, R., Wallin, H. H., “Pure refrigerant lubrication technology in oil-free centrifugal compressors”, SKF Evolution, No. 1 2017, pp. 26-30. http://evolution.skf.com/pure-refrigerant-lubrication-technology-in-oil-free-centrifugal-compressors

[5] Morales-Espejel, G.E., and Brizmer, V. (2011), “Micropitting Modelling in Rolling-Sliding Contacts: Application to Rolling Bearings”, Tribol. Trans., 54(4), pp. 625-643.

[6] Brizmer, V., Gabelli, A., Vieillard, C., and Morales-Espejel, G.E. (2015), “An Experimental and Theoretical Study of Hybrid Bearing Micropitting Performance under Reduced Lubrication”, Tribology Transactions, 58, pp. 829-835.

[7] Morales-Espejel, G.E., Gabelli, A., “The behaviour of indentation marks in rolling-sliding elastohydrodynamically lubricated contacts”, Tribology Transactions, 54, pp. 589-606, 2011.

[8] Morales-Espejel, G.E., Gabelli, A., “The progression of surface rolling contact fatigue damage of rolling bearing with artificial dents”, Tribology Transactions, 58, pp. 418-431, 2015.

[9] C. Vieillard, Y. Kadin, G.E. Morales-Espejel, A. Gabelli (2016), “An experimental and theoretical study of surface rolling contact fatigue damage progression in hybrid bearings with artificial dents”, Wear, pp. 364-365, pp. 211-223.

[10] Morales-Espejel, G. E., Brizmer, V., Stadler, K., “Understanding and preventing surface distress”, SKF Evolution, No 4 2011, pp. 26-31. http://evolution.skf.com/understanding-and-preventing-surface-distress

[11] V. Strubel, N. Fillot, F. Ville, J. Cavoret, P. Vergne, A. Mondelin, Y. Maheo., “Particle entrapment in hybrid lubricated point contacts”, Tribology Transactions 2016, VOL. 59, No. 4, pp. 768-779.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Zero-Max Load Adaptors Connect Pump Impellers in Underwater Applications

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.