SPS 2019 Preview: Mayr Power Transmission

The ROBA-brake-checker module by Mayr Power Transmission is not only able to monitor and supply safety brakes without the use of sensors—it also supplies data, and therefore provides intelligent safety. At the SPS 2019 in Nuremberg, the company is presenting new designs of the module (Hall 4, Stand 278). This opens up new possibilities for brake monitoring – in particular also for safety brakes in servomotors and for applications in the fields of robotics and automation.

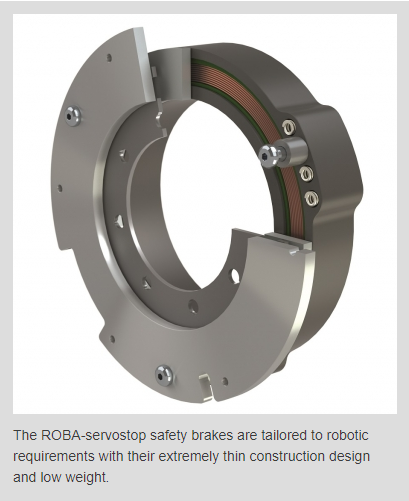

The ROBA-servostop series is ideal for installation into servomotors. A special hollow shaft design in slim constructional design and of a low weight has been especially tailored to requirements in robotic applications. In addition, the company has a fluid-free linear brake in its portfolio with its ROBA-linearstop in electromagnetic design, which has been designed to secure gravity-loaded vertical axes. This brake type is used in applications in which compressors or units for compressed air or oil hydraulics are not available or are unwanted - such as in the field of medical technology or the food or pharmaceutical industry, where high hygiene standards are required.

The ROBA-brake-checker module works without sensors. It detects the movement of the armature disk through extended analysis of current and voltage, and knows what condition the brake is in. In addition to the switching condition, temperature and wear, the ROBA-brake-checker also monitors the pull-in distance or tensile force reserve, i.e. whether the magnet is still able to attract the armature disk. With the new module, substantially more parameters are thus depicted than with microswitches and sensors. On reaching the tensile force reserve, the ROBA-brake-checker emits a warning signal early enough so that a certain operating time for the brake is still possible.

With its ROBA-brake-checker, Mayr Power Transmission offers an intelligent solution for the sensorless monitoring of electromagnetic brakes in its standard portfolio. "Users are able to integrate the module easily and quickly into machines and systems without having to intervene in the 'converter' or 'control' components," explains Product Manager Andreas Merz. "In this way they don’t take any risks as they don’t have to validate limit values and data themselves. We supply the ROBA-brake-checker ready for installation and test all values beforehand. For users, this means a plug-and-play solution, so to speak."

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ICL Boulby sets new weekly polyhalite mining record

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.