ECM Prototypes Motors for Medical Devices

ECM has integrated its printed circuit board (PCB) stator technology within several medical devices. Recently, ECM prototyped motors for two very different medical applications. The first, built for a medical robotics company, actuates the elbow joint of an orthosis. The second prototype was designed with an international medical device OEM to show the advantages of integrating an ECM motor into their portable O2 concentrator.

ECM's PCB stator technology and optimization software, PrintStator, benefit the medical industry in many ways. The planar form factor and minimal axial thickness of this technology allows for small, lightweight motors for portable systems. ECM’s increased efficiency reduces energy cost and, for portable systems, extends battery life. ECM’s flexible form factor enables compact integration with a variety of torque multipliers creating systems with high torque density. Reduced raw materials and PrintStator’s utilization of well-established PCB manufacturing processes reduces cost and lowers environmental impact.

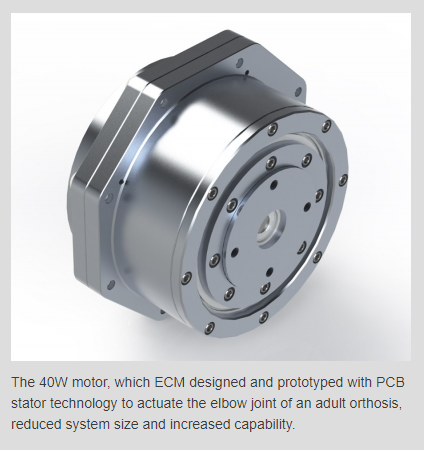

The 40W motor, which ECM designed and prototyped with PCB stator technology to actuate the elbow joint of an adult orthosis, reduced system size and increased capability. The concise combination of a harmonic drive and ECM’s axially thin motor created a low volume system with high torque density, enabling patients to wear a long sleeve shirt over top the brace and lift heavier items. ECM is currently collaborating with this medical robotic company to finalize system design.

ECM’s oxygen concentrator prototype reduced motor axial thickness by 60% and reduced system noise significantly. This compact solution required less raw materials and a reduced manufacturing cost compared to the current concentrator package. ECM is currently working with the OEM to optimize the design in order to capitalize on ECM’s motor advantages and further improve portability, reduce noise and minimize the cost responsibility of the patient.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Baldor Enhances Same-Day Gearbox Assembly Operations

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.