QuesTek Announces High-Performance Stainless Steel Material for AM Applications

QuesTek Innovations LLC, recently announced a stainless steel composition for powder bed fusion additive manufacturing (AM) for use either in the as-printed condition or with a single low-temperature heat treatment. This development is significant because it allows for production of complex, high-strength stainless parts via AM, comparable to wrought 17-4 PH, but without the need for expensive cryogenic processing or high-temperature heat treatment. The project has been funded by the US Navy Small Business Innovation Research program.

Commonly used 17-4 steel in AM often requires higher-cost argon-atomized powder to avoid retained austenite issues and it yields poor properties; however, even properties of argon-atomized 17-4 properties fluctuate widely and are sensitive to the feedstock composition.

Commenting on this development, Dr. Dana Frankel, QuesTek manager of design and product development said, “With QuesTek’s QT 17-4 powders, a fully martensitic microstructure is achieved in the as-printed condition. The high temperature solution heat treatment process, required for conventional 17-4, is not needed for QuesTek’s alloys, and the resulting properties have less variation.”

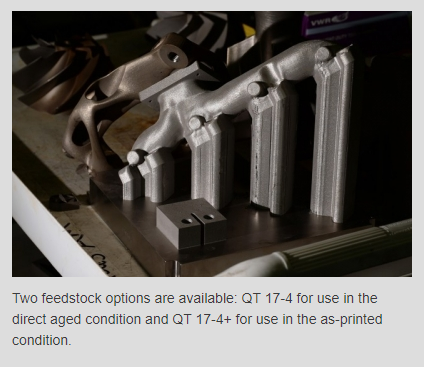

Two feedstock options are available: QT 17-4 for use in the direct aged condition and QT 17-4+ for use in the as-printed condition. The corrosion resistance and fatigue performance of both designed AM alloys is equivalent or improved over AM material printed using commercially available 17-4 powders.

Although QuesTek’s initial effort has focused on powder-based AM, it plans to demonstrate in one or more wire-based AM processes to enable larger component production at lower cost.

QuesTek’s new 17-4 powders can be used in a wide range of industries, including aerospace, defense, medical, chemical processing and energy. QuesTek’s powder was developed using its proven Integrated Computational Materials Engineering (ICME) technologies and Materials by Design approach.

QuesTek is in discussions with commercialization partners including alloy producers, metal AM machine manufacturers and service bureaus to license these technologies and accelerate commercial adoption.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Baldor Enhances Same-Day Gearbox Assembly Operations

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.