Schaeffler Readies Launch of End-to-End Wireless Sensor Solution with OPTIME

Schaeffler has more than 134 years of experience manufacturing bearings under the FAG, INA and LUK product brands. For years, the company has offered scalable condition monitoring systems tailored to meet the specific requirements of each end user. PTE recently caught up with Schaeffler Manager of Condition Monitoring-Americas, Frank Mignano, to discuss the evolution of condition monitoring for bearings and the upcoming introduction of their next-generation condition monitoring platform called OPTIME—a cost effective, IIoT-focused end-to-end wireless sensor solution with cloud computing analytics.

Building on Bearing Knowledge As a solutions provider, Mignano said that Schaeffler’s goal is to be able to handle any application in the most efficient way possible, while providing the most value to the end user. Schaeffler’s condition monitoring systems are designed to be scalable, depending on the specific end user’s requirements. “This means we can monitor a few bearings or many bearings in a facility—or anything in between—because expanding our systems is easy. While multichannel solutions like Schaeffler’s ProLink system can handle a cluster of critical bearings on a drive system gearbox, for example, OPTIME can handle the remainder of the balance of plant rotating assets in a facility,” Mignano said. Over the years, condition monitoring systems have moved toward smaller, less expensive designs that are more tightly integrated with end user facilities, while maintaining a clear focus on IIoT and the advantages offered by cloud computing. “Integration is achieved by sharing speed and load data from existing site systems, while also sending vibration and temperature data to existing plant assets such as a PLC or DCS system. Another challenge for any company in the condition monitoring business is to interpret the complex vibration data and turn it into actionable information for the end user,” he added. Mignano said that Schaeffler has accomplished these objectives with OPTIME. For example, using advanced, proprietary algorithms, Schaeffler can combine data such as acceleration, demodulation, and kurtosis into actionable information for the end user. “Our artificial intelligence algorithms enable us to determine (in this example) whether all three variables are elevated and, additionally, whether bearing frequency peaks are present in the demodulation or acceleration spectrum data. This would indicate that the bearing being monitored is in a critical state and needs to be changed within the next two months. Much of our work has been focused on taking the mystery out of vibration analysis, while creating a tool that can easily provide maintenance planning help for the end user,” Mignano said.

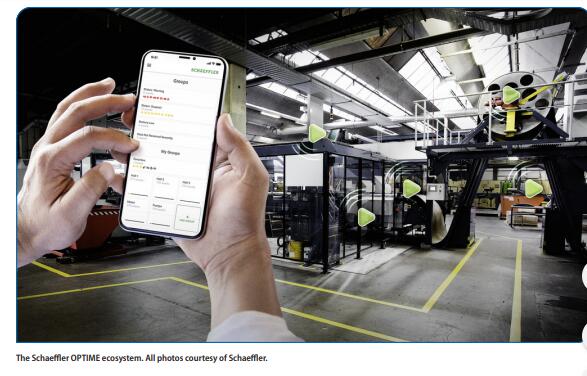

What is OPTIME? According to Mignano, OPTIME is a fully wireless, battery-powered vibration and temperature monitoring system designed to be deployed on all balance of plant assets in a manufacturing facility. (In a large paper mill, for example, an OPTIME system could encompass 2,500 sensors deployed throughout the site. A smaller cement mill, on the other hand, might require 500 sensors.) Each OPTIME sensor is designed to last five years, and it will store seven sets of overall data every four hours—plus a Time Waveform/FFT once per day. “OPTIME communicates via a self-healing MESH network to a cellular gateway—each of which can process up to 70 sensors—that sends the data to the Schaeffler Cloud, where advanced analytics are performed. The actionable information is then available on a smartphone app (available for iOS and Android) as well as on the Schaeffler Cloud. Costeffectiveness and ease-of-use were two of the main targets that were clearly met during the design and implementation of the technology,” he added.

Condition Monitoring Evolution The technology to be able to detect rotating equipment and specifically bearing defects so that maintenance can be identified, planned, and executed at minimal cost has existed for years. “This is the goal of portable as well as installed Predictive Maintenance (PdM) technologies. Each has its own unique challenges: An installed system is not only (relatively) expensive to purchase, but also expensive and time-consuming to install and maintain over the years. Portable vibration systems, meanwhile, are very effective, but they are manpowerdependent and time-based. This means that certain failures can occur between regular collection intervals,” Mignano said. IIoT has advanced sensor technology into a fit and form factor that makes it cost effective to monitor the customer’s entire array of rotating assets online, thereby reducing Total Cost of Ownership (TCO) and enabling data and information to be available on each asset and for all pertinent employees—24/7. A “smart” bearing can tell you when it needs to be re-lubricated or if it is failing and needs to be replaced. “Instead of suffering a bearing failing without warning during a critical production run, technologies such as OPTIME—with its ability to provide over 1,200 data points per sensor per month—can give you advance warning when bearing conditions change. Then it simply becomes a matter of planning the repair during a normal maintenance outage, when personnel are available, and parts have been ordered. The goal of a smart bearing is to minimize interruptions to production schedules,” Mignano said. Technologies like ProLink and OPTIME—and even Schaeffler’s innovative Concept1 automatic lubricator—are more critical than ever during the coronavirus pandemic, as many employees are not able to make it to the factory to perform normal maintenance checks or re-lubricate bearings. This is where automation takes over. This scenario is particularly prominent in the food and beverage industry where less human contact is practically required. Tools like OPTIME are a cost-effective and easy-to-deploy solution to a) automate the required data collection and b) utilize years of experience embedded into the device’s advanced algorithms to provide actionable information about the condition of all of the bearings inside a facility’s rotating assets. Moreover, automatic lubricators such Schaeffler’s Concept1 can ensure clean lubrication is automatically supplied at the proper intervals.

Bearing Healthcare—Next Steps Mignano believes the next step after OPTIME technology would be to provide bearings with sensors -embedded into or adjacent to the raceways—that capture critical bearing health information such as vibration, temperature, load, speed and lubrication condition, and then make this data available to the end user as actionable information. “The ultimate solution would be to implement monitoring tools that would enable a simple, easy to read and reliable “Bearing Health Dashboard” (kind of like your car’s fuel gauge) that would indicate how much life is left in the bearing—is it full or closer to empty?” OPTIME is set to officially launch in the United States in January 2021.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Baldor Enhances Same-Day Gearbox Assembly Operations

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.