World's First 100% Bioplastic Bearing Cage-Supporting Carbon Neutrality with Environmentally Friendly Products from NSK

NSK is committed to realizing a carbon-neutral society. As part of these efforts, in November 2021, NSK developed the world's first bearing equipped with a cage made of 100% plant-derived bioplastic for use in air conditioner fan motors. In this issue, we talk to the engineers behind this development about the background of the project and what drove them.

100% bioplastic bearing cage developed

NSK has always been committed to protecting the global environment, as indicated in its Mission Statement. Over the decades, this commitment has driven the development of many environmentally friendly technologies, products and materials. NSK's bearings-our mainstay product-are intrinsically eco-friendly because they help save energy by reducing friction and smoothing mechanical movement.

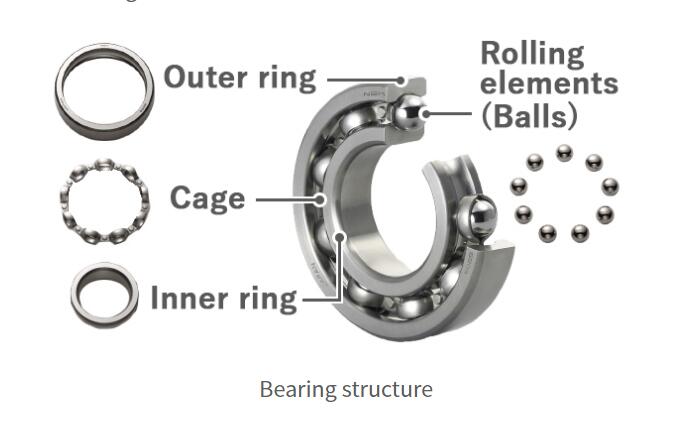

Our team carries out research into the plastic and rubber materials used in NSK products. In order to reduce CO2 emissions related to bearing materials, we developed a cage comprised only of bioplastic, which is produced entirely from renewable plant resources. Bearings are composed of balls or rollers (rolling elements) between the inner and outer rings. A cage is used to space the rolling elements at regular intervals and enable the bearing to rotate smoothly. The cage is therefore a critical component of the bearing.

Plastic derived from fossil fuels is typically used to make these cages. This plastic is made from petroleum pumped from the ground, a process which releases CO2 into the atmosphere. CO2 is also emitted when the plastic is incinerated at the end of the product's lifespan. In contrast, the bioplastic cage we developed uses sesame plants as the raw material for the plastic. Since plants absorb CO2 from the atmosphere during photosynthesis, even if CO2 is emitted during incineration of bioplastic, it will be no more than the amount initially absorbed by the plants. Therefore, bioplastic CO2 emissions are basically net zero. Bioplastic raw materials are produced by cultivating, harvesting and processing plants, and these processes emit less CO2 than the processes used to make plastics from fossil fuels. Our bioplastic cage can reduce CO2 emissions by 91% over the product lifecycle compared to conventional cages (polyamide 66).

NSK has been developing and manufacturing bearings for over 100 years. We made the most of our expertise to develop a cage made of environmentally friendly materials without any compromise to quality. A bearing cage needs to be strong enough to withstand heat and load when in use. At the same time, the material needs to be easy to mold and also flexible enough to bend during bearing assembly. We leveraged materials technology, one of NSK's Four Core Technologies, to evaluate the potential of new materials to meet the requirements for bearing cages. The result is environmentally friendly cage that also delivers heat resistance and strength comparable to a conventional one.

We also employed NSK's digital twin technology in the development of the new cage. NSK uses the digital twin approach to achieve high quality and efficiency in product development. Digital twin technology helps create innovative, unexpected solutions, and utilizes both the ability to gain insight into phenomena occurring in the real world, and the ability to apply reasoning by using technology to create a digital model and understand the essence of the underlying issue. We began by using digital technology to analyze how the material might behave, and predicted its molding potential and likely performance. By then creating a real prototype based on the digital results, we eliminated the need to make multiple prototypes, shortening the trial and error process. This made the development so efficient that it only took one-third of the usual time. As environmental awareness grows, I am delighted that we were able to rapidly develop this world-first product to help promote carbon neutrality.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Schaeffler Organizes Worldwide Climate Action Day

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.