Innovative technologies for robotics and smart maintenance solutions

Schaeffler’s RT1-T precision strain wave gear with integrated torque sensor opens up new application potential in the field of lightweight robotics.

Standard and high torque precision strain wave gear with optimally matched gearbox main bearing for compact, powerful, and cost-effective robot joints

Integrated torque sensors allow cobots to be used in new and sophisticated areas of application

The world’s first smart lubricator eliminates time-consuming routine tasks and simplifies the process of supplying lubricant to machines

At SPS 2022 in Nuremberg, the focus will be on smart and digital automation solutions. And that is exactly what Schaeffler will be presenting: innovative system components for more performance, precision, and cost effectiveness in a wide range of applications for industrial and lightweight robotics. With its intelligent maintenance solutions for predictive maintenance, Schaeffler is responding to current industry requirements for reduced downtimes and greater safety.

Precision strain wave gear for robotics

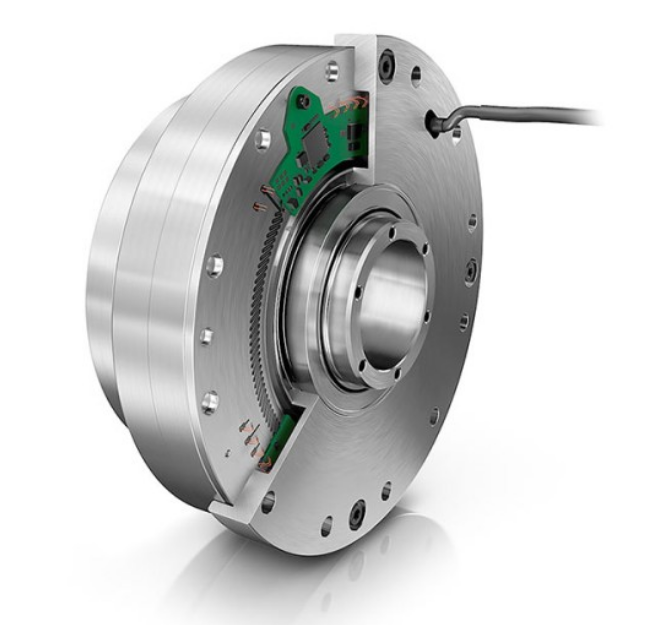

Schaeffler will introduce two series of precision strain wave gears for robotics applications to industry professionals at SPS 2022: RT1 for the high-torque range and RT2 for standard torque applications. The RT2 series offers an extremely wide range of variants and very easy integration into robot design. It covers around 80 percent of standard cobot applications. Thanks to their high torque density, the RT1 precision strain wave gears allow for especially compact articulated arms for higher than average loads. Their backlash-free, wear-resistant toothing guarantees maximum positioning accuracy over the entire service life of the gear. The low weight and compact design make RT1 precision strain wave gears ideal for use in cobots.

The precision strain wave gears from the high torque range are also available with integrated torque sensors (option RT1-T). Compared with many of the solutions available on the market, the sensor technology delivers precise signals without any loss of rigidity in the overall mechanical system. The integrated sensor system supports safety functions and highly accurate positioning and process control, and can be used for active vibration compensation. As a precision strain wave gear that is currently unrivaled, the RT1-T has the potential to tap into a wide range of new application areas in lightweight robotics, where reliably high accuracy is required. Typical applications could include e.g. machine tool construction, industrial production, the food and beverage sector, or medical technology.

Optime C1 smart lubricator

Optime C1, the world’s first smart lubricator launched on the market by Schaeffler last year at a virtual event, delivers an extremely simple yet safe and efficient maintenance process, especially in the case of sensitive or complex applications. As a component of the integrated IoT solution OPTIME Ecosystem, it enables the lubricant management of an entire production line to be fully automated, which in turn simplifies the maintenance process. The smart monitoring and automated processing, combined with intuitive web- and app-based operation, ensure the safe and economical use of lubricant. At the same time, Optime C1 prevents premature failures due to incorrect lubrication and thus improves the availability and service life of the production equipment to be monitored such as drives, bearings or gearboxes.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Built-in Bearing Extraction Bolts for easy maintenance!

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.