Mastercam's mill solutions

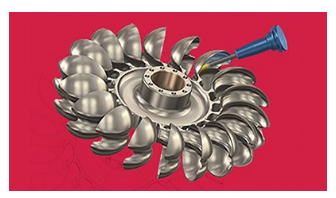

Mastercam Mill offers expanded machining flexibility and an increased emphasis on speed and automation. Multi-axis features, 3D enhancements, and 2D high-speed toolpaths combine with dozens of additional new enhancements in a software package intended to improve shop floor productivity.

Here are some significant highlights and new functionality in Mastercam Mill:

Multi-axis Improvements

Morph, Parallel, Along Curve, and Project Curve are no longer individual toolpaths. Instead, users can now find the same functionality inside the Multi-axis Unified toolpath, which allows for more flexibility in cut pattern when programming multi-axis, all within a new advanced feature set and consolidated, easy-to-use interface. A new Feed Rate Control page consolidates the feed rate control options, making the options easier to find and simplifying your workflow.

3D Enhancements

The Dynamic OptiRough and Area Roughing toolpaths can now be aware of undercut stock conditions, resulting in improvements to the toolpath motion, including less air cutting. Equal Scallop is now a fully stock-aware, semi-finishing toolpath that now identifies material left in corners and will machine with a single pass or with multiple passes to ease into the material. With the new linking parameters in OptiRough toolpaths, you can control and optimize your air cuts which allows for greater efficiency in roughing toolpaths when transitioning between passes or when in air.

2D Enhancements

The Slot Mill toolpath no longer requires two parallel walls when selecting the machining geometry. You are now able to select any closed chain. 2D Contour Profile Ramp now supports the Override feed rate option which allows you to specify a feed rate for the entry or exit move, allowing you to slow down feed rates as you are engaging material. When you drag and drop items in the Toolpath Hole Definition panel, Mastercam now provides visual cues for the drop location. Also, the drag-and-drop icon now indicates whether you are dragging a single item or multiple items.

Additional Improvements in Mastercam Mill that benefit efficiency include:

• The Tool page and Toolpath parameters tab for milling toolpaths have been redesigned to provide a better, user-friendly layout.

• Automatically Detecting and Including Stock for Z depths is now included for 3D high-speed toolpaths.

• New Feed Rate Control page for Multi-axis toolpaths which consolidates the feed rate control options, making them easier to find and simplifying your workflow.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next UniWest's EddyView II portable eddy current flaw detector

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.