Bearing Design Considerations for the Food Processing Industry

Materials, closures and lubrication options must be properly selected to ensure the optimal performance of bearings used in this machinery.

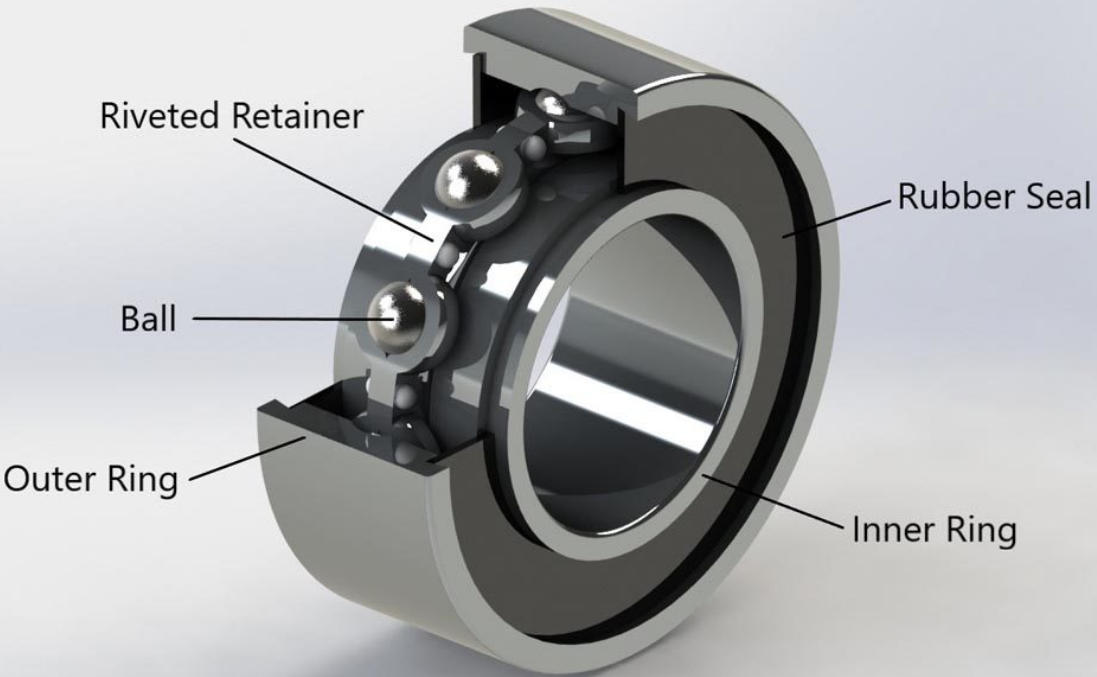

Basic components of a sealed ball bearing (lubrication not shown).

Food production is an essential, but often overlooked, component of our food chain. Reliable, efficient machinery plays a key role in the food processing industry—and ball bearings are essential to the performance of this equipment. Designers and engineers are faced with important decisions when specifying bearings used in food processing equipment, which must withstand challenging operating environments while meeting stringent safety requirements.

Regulatory Compliance

The U.S. food processing industry is heavily regulated by government agencies. Two federal agencies dominate this regulatory oversight: The Food Safety Inspection Service of the U.S. Department of Agriculture (USDA-FSIS) and the Food and Drug Administration (FDA). USDA-FSIS is responsible for meat, poultry and egg processing while the FDA oversees all other food processing businesses. State agencies also play an active role in oversight. All materials, including lubricants, must comply with applicable state and federal food processing requirements. Depending on the application, components used in machinery (such as a complete bearing) may require regulatory approval as well.

Hybrid ball bearing, made from stainless steel rings, ceramic silicon nitride balls, and a fluororesin cage (lubrication and enclosure not shown).

Bearings used in food production equipment must be manufactured from high-purity materials. While bearing rings are commonly produced from SAE 52100 chrome steel, food processing applications generally require rings made from martensitic stainless steel (such as AISI 440C). This stainless steel offers the best combination of corrosion resistance and fatigue life. For additional corrosion resistance, nitrogen-enhanced martensitic stainless steel can be used. This steel is more expensive than 440C but offers five times the corrosion resistance. It also exhibits extended fatigue life and very low noise levels due to its fine crystalline structure, which contains small chromium nitrides (as opposed to larger chromium carbides).

Bearing components such as shields, slingers and cages should be manufactured from AISI 302 or 304 austenitic stainless steel. Bearing rings can also be manufactured from AISI 300 series stainless steel (which has outstanding corrosion resistance compared to 400 series stainless steel) but is typically not used in food processing applications due to a compromise in fatigue strength. Load ratings for ball bearings with 300 series stainless steel rings are approximately 20 percent of the load ratings for bearings with 400 series stainless steel rings. However, if the application loads are very light and corrosion is a concern, 300 series stainless steel can be considered an acceptable option.

In applications where bearings are required to operate immersed in water or be resistant to chemical attack, hybrid ball bearings should be used. These bearings are constructed with rings made from martensitic stainless steel and balls produced from ceramic silicon nitride. The bearing cage is made from a fluororesin such as Teflon, which is water-resistant, inert to most chemicals, and reduces friction. Hybrid bearings are maintenance-free and extend service life in these severe operating conditions.

Mounted bearing units are used extensively in food processing conveyors and similar equipment. This type of component often consists of a radial ball bearing, known as an insert, mounted within a housing. Various housing styles allow for different mounting arrangements. Pillow blocks, one of the more common types of housings, are used for low torque, light load applications. In the meat and poultry sectors, high strength housings called plummer blocks are often required to transfer ample power and support heavy loads.

Insert bearings should be produced from 440C stainless steel. AISI 52100 chrome steel bearings, either plated with zinc chromate or coated with black oxide, are another good option to consider. Several choices are available for corrosion resistant, food-safe housings. Cast or ductile iron housings with electroless nickel plating are a cost-effective solution that offers high strength and can withstand the effects of most washdowns. Cast 300 series stainless steel, however, is the best option when facing high concentrations of chlorine or other chemicals in cleaning solutions. Thermoplastic housings are an effective alternative for use in high moisture and caustic environments. While not as strong as iron or steel, these housings are lightweight and will not chip or flake as will a plated housing. Regardless of housing material, all surfaces should be smooth with flat mounting bases and be free from recessed areas. This type of design allows for effective washdowns and eliminates the possibility of food by-products or debris getting caught in the housing, which can lead to bacterial growth.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next KING TO HOST PRI TECH SEMINAR AND LAUNCHES CAN-AM BEARINGS

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.