What factors are related to the lifespan of bearings

What Factors Are Related to The Lifespan of Bearings

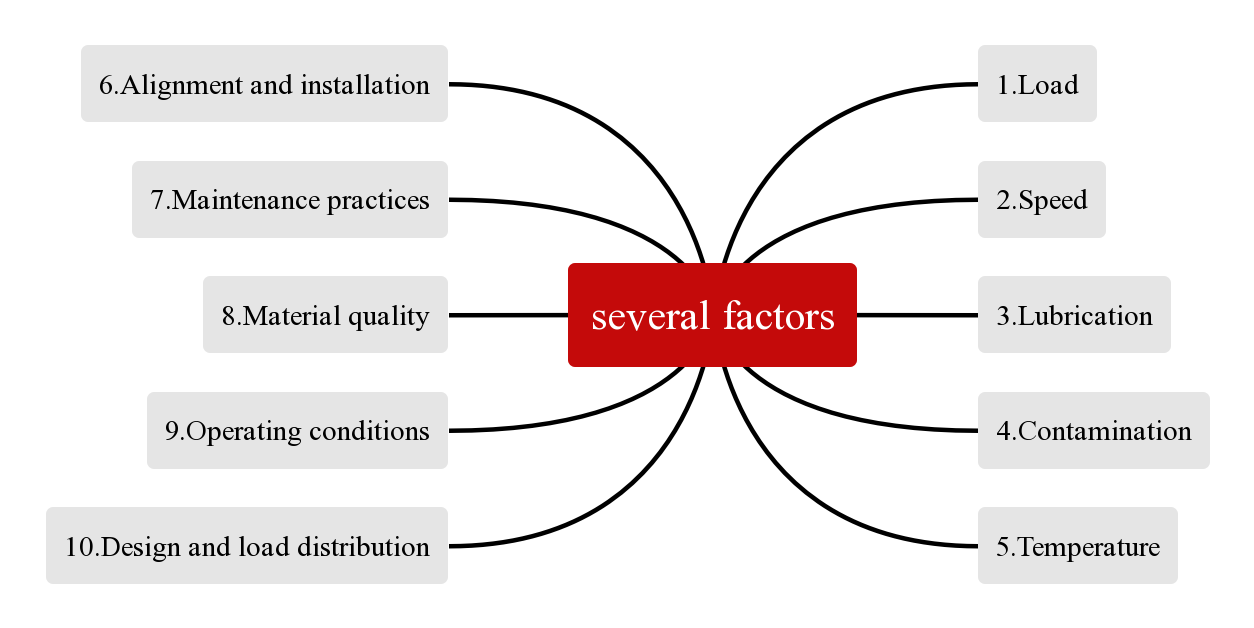

The lifespan of bearings, or their overall longevity, is influenced by several factors, including:

1.Material Selection: The choice of bearing material is critical in determining its lifespan. Bearings are commonly made from materials such as steel, ceramic, or various alloys. The selection of the appropriate material should consider factors such as load capacity, corrosion resistance, and fatigue strength to ensure optimal longevity.

2.Load Capacity: The maximum load that a bearing can withstand without experiencing excessive wear or failure is an essential consideration for its lifespan. Bearings should be chosen based on the expected loads they will endure during their service life. High loads beyond the bearing's capacity can cause premature wear and reduce lifespan.

3.Lubrication: Proper lubrication is vital for minimizing friction and reducing wear in bearings. Lubricants create a film between moving surfaces, reducing direct contact and frictional heat. Insufficient or improper lubrication can lead to increased friction, wear, and ultimately, a shorter lifespan.

4.Contamination Control: Preventing the ingress of contaminants, such as dust, dirt, moisture, or debris, is crucial for extending the lifespan of bearings. Contaminants can accelerate wear, cause abrasive damage, and compromise the lubrication properties, leading to premature failure.

5.Operating Temperature: The operating temperature range is a critical factor affecting bearing lifespan. Excessive heat can degrade the lubricant, increase wear, and reduce the material strength. Similarly, extremely low temperatures can impact the bearing's performance and increase the risk of brittle fracture. Operating within the recommended temperature limits helps ensure longer bearing life.

6.Mounting and Installation: Proper installation practices significantly impact bearing lifespan. Incorrect mounting techniques, misalignment, or excessive preload can introduce stress concentrations, leading to premature failure. Following manufacturer guidelines for installation, including torque specifications and alignment procedures, is crucial for maximizing bearing life.

7.Maintenance and Condition Monitoring: Regular maintenance, including inspections and lubrication, is vital for identifying early signs of wear or damage. Condition monitoring techniques, such as vibration analysis or temperature monitoring, can help detect abnormalities and allow timely intervention to extend bearing life.

8.Operational Speed: The rotational speed at which the bearing operates affects its lifespan. High-speed applications generate more heat and forces, increasing the wear and fatigue rate. Bearings designed for specific speed ranges should be chosen to ensure longevity.

9.Environmental Factors: Environmental conditions, such as humidity, corrosive agents, or exposure to chemicals, can impact bearing lifespan. Corrosion-resistant bearings or appropriate protective measures should be employed when operating in harsh environments.

10.Quality and Reliability: The overall quality and reliability of the bearing, including manufacturing standards and adherence to specifications, can directly influence its lifespan. Choosing reputable manufacturers and suppliers known for producing high-quality bearings helps ensure their longevity.

It's important to note that these factors are interconnected, and addressing multiple factors simultaneously can help maximize bearing lifespan. Additionally, proper maintenance practices, adherence to operating guidelines, and regular inspections are key to extending the lifespan of bearings in any application.

Our main products are RB, RA, CRBH, SX, RU, XU, XSU series crossed cylindrical roller bearings, XR, JXR crossed tapered roller bearings, YRT, YRTS, ZKLDF series rotary table bearings. Many models are bulk on the stock. Diameter range from 20 mm to 2,000 mm. All products are produced by advanced CNC machines and are 100% inspected. The Precision class is P5 P4 and P2. The warranty is 12 months.

Contact

Company:Luoyang EFANT Precision Bearing Manufacturing Co. Ltd

Address:No. 9 Jingjin North Rd, Luoxin Development Zone,

Xin'an County, Luoyang City, Henan Province 471003, China

Tel:86-379-80887690

export@efindbearing.com

https://www.efindbearing.com/contact-us

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next How to handle the temperature increase of precision bearings

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.