SPRUTCAM X AND SPRUTCAM X ROBOT 17.0.12

SprutCAM Tech, an independent developer of CAD/CAM/OLP software, is pleased to announce the release of Update 17.0.12 of its software.

Key Features and Enhancements of SprutCAM X and SprutCAM X Robot 17.0.12:

Plunge Parameters: Users can now specify tool design features like the maximal ramp angle and minimal cut diameter. The machining simulation will take these parameters into account and provide an error message if the values exceed the specified limits.

In certain situations, it is necessary to customize the tool plunge parameters independently of the tool's predefined specifications. To avoid making frequent adjustments directly to the tool, users can easily configure distinct plunge values for simulations by accessing the "Check for plunges" option within the Parameters tab for each specific operation.

Additionally, SprutCAM X provides the flexibility to disable the "Check for plunges" feature entirely, making it particularly useful in specialized applications like machining foam components.

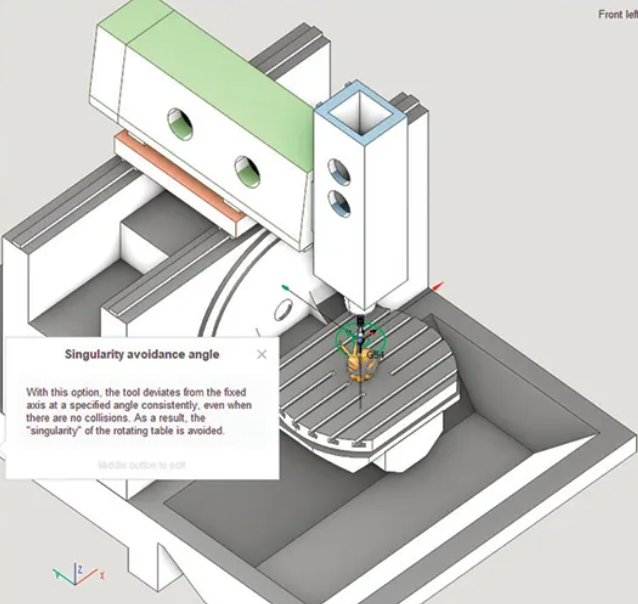

Singularity Avoidance Angle: This innovative option ensures that the tool deviates from the fixed axis at a specified angle consistently, even in the absence of collisions. This helps avoid the "singularity" of the rotating table, improving the overall machining process.

Search by G-code: The addition of a search function to G-code based operations simplifies and streamlines the workflow for users, making it easier to find specific elements within the code.

Improved User Experience:

Updated Tooltips: SprutCAM X 17.0.12 features updated tooltips for various operations, including 5D Meshing, Hole machining, 5D surfacing, Face milling, and Waterline undercut operations. These tooltips provide users with clearer and more informative guidance throughout their work.

Enhanced Toolpath Calculation: The software now employs an improved toolpath calculation algorithm for 3+2 types of machining in the Pocketing operation. This enhancement results in more precise and efficient toolpaths.

In SprutCAM X 17.0.12, numerous issues have been diligently addressed and resolved to enhance software functionality. These improvements encompass a wide range of areas, from toolpath control in 5D surfacing operations to fixing errors encountered when working with outdated post processors. The update also rectifies problems related to model displays in multi-part projects, critical errors during turning contour operations, and issues surrounding the handling of robotic cell kinematics. Additionally, issues with rendering milling tools, tool tip visualization, and orientation vectors in 5D contouring operations have been successfully tackled.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next TITAN TOOL SUPPLY'S 16-LED RING ILLUMINATOR

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.