Spindle Bearings—Potential Damaging Mechanisms and Mitigation

Exploring contact conditions in both steel-steel and hybrid ceramic bearings

Introduction

Application conditions of super-precision spindle bearings can be represented in a simple way by a diagram involving bearing speed and bearing load. Bearing speed is represented by the quantity ndm where n is the bearing rotational speed in rpm and dm represents the bearing mean diameter in mm. In this schematic diagram (Figure 1) different application conditions can be distinguished. Bearing load is better represented by the maximum Hertzian contact pressure (Ph) in the inner ring of the heaviest loaded rolling element. In this diagram several application areas (platforms) can be found: (i) performance, (ii) extreme and (iii) ultrafast.

Bearings in this schematic might have different damaging mechanisms according to their relative position respect to load and speed axes. It is important to understand these mechanisms to properly select a bearing. In the present article the main damaging mechanisms covering all regions of Figure 1 will be explained, besides some potential solutions or mitigation actions will be mentioned.

Performance Series

The operation zone here is the classical one for “standard” super-precision bearings, steel-steel and hybrid ceramic. Typical damaging mechanisms here are indentations and surface distress. Looking in detail of each one of them follows.

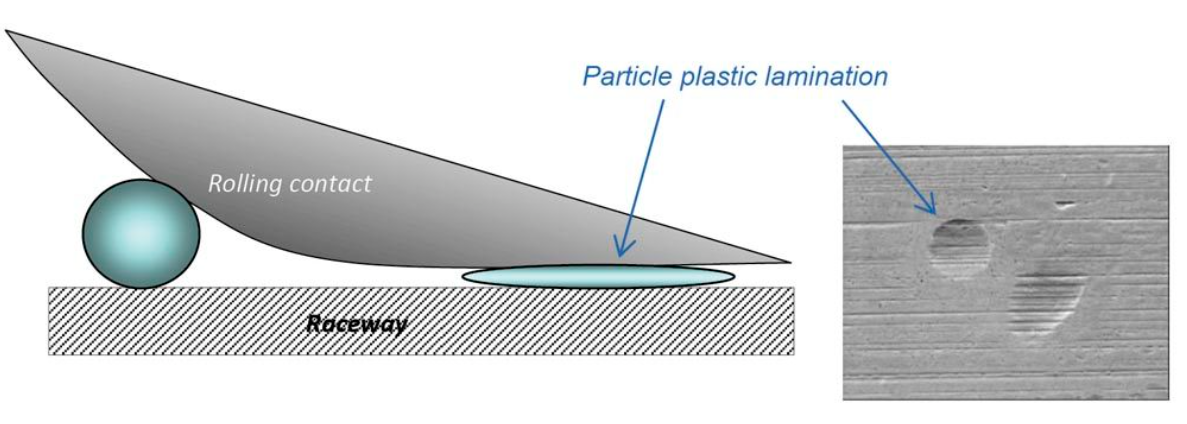

Solid Particle Indentations

For a solid particle to be damaging in a bearing contact, it must be entrapped and it must be big enough to create an indentation. The hardness of the particle also plays a role, hard-brittle particles will chatter and will create very tiny but sharp indentations, softer particles (metals and fibers) will create indentations with rise material around (shoulders), see Figure 2. However, fiber particles in general will produce very shallow indents (basically negligible). The process of indentation has to do with the material of the particle and the material of the raceway, the harder the particle the smaller but the sharper and deeper the indentation becomes. The harder the raceway the shallower the indent that will be created. There are many works in literature that show indentation mechanisms from particles. However, entrapment and indentation together have been studied in the past by SKF. In Ref. 1 a simple entrapment model is derived for assumed spherical particles, but it can be generalized to any geometry because the relevant geometrical aspect is the local radius of curvature of the particle. With this model the plot of Figure 3 has been obtained, where the maximum diameter of the particle that can be entrapped is given as a function of the rolling bearing diameter and the coefficient of friction between the rolling bearings walls (raceway) and the particle.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Beyond Bearings: Unleashing the Potential of Ball Splines in Robotic Designs

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.