What is the structure of YRT turntable bearings?

What is the structure of YRT turntable bearings?

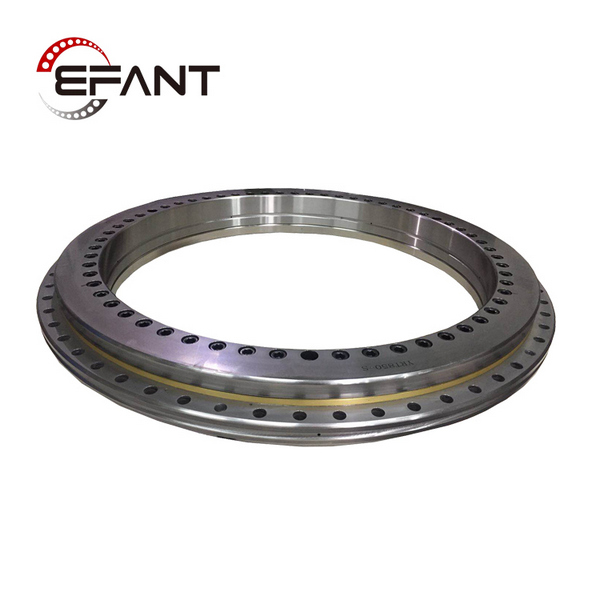

The development of YRT turntable bearings has high rotational motion accuracy, which can withstand radial working loads, bidirectional selection of axial loads and overturning moments. They are suitable for situations that require high precision and can withstand combined actual loads, such as turntables, flower discs, milling heads, and reversible fixtures. What is the structure of YRT turntable bearings?

The YRT turntable bearing rings have their own mounting holes, making installation very simple and convenient. The axial and radial preloading after installation ensures high accuracy and rigidity. The size series is complete and suitable for studying the reasonable selection and use of turntables of different sizes; The appearance of turntable bearings in different product series. Choose a series with the same installation size that is suitable for different environmental requirements. The temperature range of the working environment for bearings in the YRT, YRTS, and ZKLDF series research turntables is -30C to+120C.

1. YRT Standard Series:

The YRT series turntable bearings are designed with a combination structure of radial fully loaded rollers and two sets of thrust roller cage components. There are outer circles, L-shaped inner rings, and two inner rings, with installation holes on the inner and outer rings. Pre loads are added before leaving the factory, which not only simplifies the component structure but also reduces the installation workload and high installation requirements. Therefore, for low-speed applications that require high precision, high rigidity, and the ability to withstand combined workloads. For short-term operation of indexing tables, rotary milling heads, etc., it is advisable to use YAT series turning bearings.

The YRT standard series bearings have two types of axial and radial runout accuracies, and customers can choose them through reasonable design according to their own needs.

2. YRTS high-speed series:

The YRTS high-speed development series has two auxiliary components and one radial component, which are similar to the YRT standard bearing series. The axial part mainly includes two important thrust cylindrical roller cage components, an outer ring, an L-shaped inner ring data, and two inner rings. The combination can apply preload in the auxiliary direction after installation; The radial part is a cylindrical roller cage assembly guided by a cage, which also requires a preload to be applied in the radial direction; The outer ring, L-shaped inner ring, and second inner ring all have their own installation holes, and the bearing company can connect the bolts through the network without fixing them, ensuring the transportation and handling of the system installation.

The YRTS high-speed development series turntable bearings have different external structures and dimensions compared to the YRT standard series turntable bearings, but their unique internal control system design method makes them have a higher limit speed, lower friction force throughout the entire speed range, and can be uniform. Therefore, it is suitable for applications similar to the YRT standard series but requiring lower friction and high-speed direct drive bearings, especially suitable for the selection of CNC turntable structural bearings.

YRTS Rapid Development Series

For a higher level of precision requirement, this series can also provide higher axial and radial runout accuracy.

3. ZKLDF thrust angle contact ball series:

The ZKLDF series important thrust angle contact ball bearings mainly consist of an integral outer ring, two relative inner rings, and two sets of steel balls and cages as components, with a contact angle of 60C. The outer and inner rings are equipped with mounting holes for easy installation and fixation of bearings through connecting bolts. The bearing enterprise itself can be fixed by connecting bolts to ensure system installation, transportation, and handling.

The ZKLDF thrust angle contact ball series turntable bearings have sealing covers on both sides to prevent the entry of external dirt, impurities, and leakage of internal lubricating grease.

The ZKLDF thrust angle contact ball series research turntable bearings can be lubricated with a composite barium based grease, or can also be re lubricated by utilizing the oil holes on the outer ring.

Contact

Company:Luoyang EFANT Precision Bearing Manufacturing Co. Ltd

Address:No. 9 Jingjin North Rd, Luoxin Development Zone,

Xin'an County, Luoyang City, Henan Province 471003, China

Tel:86-379-80887690

export@efindbearing.com

https://www.efindbearing.com/contact-us

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next What are the models and working principles of turntable bearings?

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.