Yokogawa launches new systems for open process automation

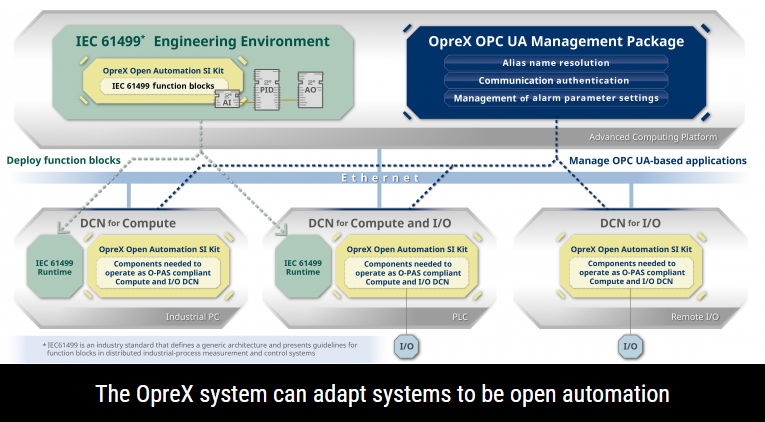

Yokogawa Electric Corporation has announced the development of OpreX open process automation (OPA) systems, named open automation SI kit and OPC UA management package. This is part of its control and safety range. Users can configure and have application portability as well as interoperability throughout components regardless of supplier, allowing end users to select best-in-class components to be integrated into its systems. Having technology that is compatible with open process automation standards (O-PAS), allows users to optimise their overall costs whilst using the latest technology in each field. Open process automation forum (OPAF) was created with the latest in IT/OT technologies along with improved cyber security and resulted in the O-PAS standard which enables a new generation of process control systems. Many process industries have to integrate multiple proprietary systems to gain production control in most process plants and facilities. These processes can include manufacturing execution systems, distributed control systems, programmable logic controllers (PLCs), and their respective human-machine interfaces. OPC UA is the standard for interoperability, meaning that data is exchanged securely and reliably in the industrial automation space and other similar industries. Industry 4.0 recognises it as a communication standard, as it has high security and can be scaled without the need for hardware or a dependent OS. For the OPA system to work and be effective, it requires devices and applications to be O-PAS compliant, as well as having mechanisms which allow control and operation as distributed control nodes (DCNs). Products must also be compatible with OPC UA management systems that run on the OPA system. This can be remedied using the OpreX open automation SI kit as well as the OpreX OPC UA management package. Open automation SI kit provides the tools to make hardware functional with OPA. The tools can enable DCN components with OPA systems. This adapts the components and makes them accessible as DCNs by creating data structures that can operate in line with the O-PAS informational model. OpreX OPC UA management package is the software that makes operations in line with OPA requirements. This manages functions such as communication authentication, alias name resolution and management of alarm parameter settings. This enables technology to be brought into an OPC UA system. PLCs and industrial PCs can be integrated into the OPA system using the integration kit and software packages. This enables them to function as O-PAS DCNs. An O-PAS process control system will be provided to customers using OPA system integrator software and other system management tools, providing an open, highly interoperable and highly secure. This is a combination of software and hardware from various suppliers. Yokogawa has been testing OPA systems using testbeds, and tests and then improving OPA technology alongside customers' needs as a proactive member of the open process automation forum. Through these tests and processes, the company has been able to evaluate and create new technologies for the market which have been field-tested.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Motion Enters into Agreement to Purchase Industrial Products Distributor

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.