Motor bearing configuration strategy: two columns and one ball structure analysis

In the bearing configuration of the motor, "two columns and one ball" is a classic shaft layout scheme. This configuration uses two cylindrical roller bearings and one ball bearing to meet specific load requirements, especially for situations where large radial loads need to be borne. This layout design divides the shaft into a locating end and a non-locating end to ensure the stability and reliability of the shaft system.

The most commonly used cylindrical roller bearings in motors are the NU and N series, which are mainly used at the non-locating end because they cannot withstand axial loads. In contrast, ball bearings are usually arranged at the locating end to ensure the correct position and stability of the shaft due to their certain axial load-bearing capacity.

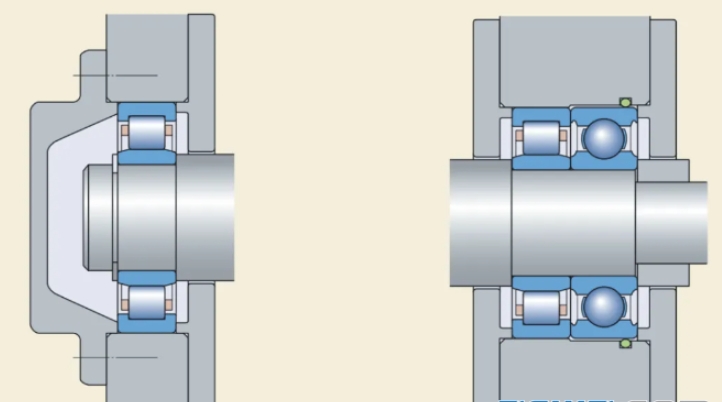

When the motor shaft system faces high radial loads, the traditional double deep groove ball bearing configuration may not be sufficient to cope with it. At this time, two cylindrical roller bearings can better support the radial load of the shaft. However, since cylindrical roller bearings do not have axial load-bearing capacity, an additional ball bearing is required for axial positioning, thus forming a "two columns and one ball" layout. As shown in the figure below, this is a typical example of a "two-column and one-ball" motor bearing configuration:

In the figure, the bearing combination on the right includes a cylindrical roller bearing and a ball bearing, which jointly assume the function of the locating end; on the left, only one cylindrical roller bearing is installed, which is used as the non-locating end. All radial loads of the entire shaft system are mainly borne by the two cylindrical roller bearings, while the axial positioning depends on the ball bearing. In order to prevent the ball bearing from being subjected to unnecessary radial loads, the radial support of the ball bearing is usually loosened during design and fixed by clamping devices on both sides. In addition, in order to prevent the outer ring of the ball bearing from moving in the bearing seat, an O-ring is usually added inside the bearing seat.

In some special application scenarios, such as when there is a large axial load or a large motor requires stronger axial positioning capability, a four-point contact ball bearing can be considered to replace an ordinary ball bearing. It should be noted that the four-point contact ball bearing is also not suitable for bearing radial loads, so radial openness must be ensured during design.

The "two-column and one-ball" bearing configuration is mainly used for medium and large motors, but is less common in small motors. For large motors, when the journal size is large, it may be difficult or costly to find a suitable deep groove ball bearing. At this time, it may be necessary to adjust the design plan according to the actual situation, or even consider abandoning the "two columns and one ball" layout.

It is worth noting that cylindrical roller bearings are very sensitive to shaft eccentricity. If the motor generates a large radial load during operation, resulting in significant bending of the shaft, it may affect the performance of the cylindrical roller bearing. In this case, the selection of bearings and the design of the shaft system should be re-evaluated.

In the "two columns and one ball" structure, since the two bearings at the locating end are placed side by side, this may affect the lubrication and heat dissipation effect. Therefore, when designing the lubrication system, it should be ensured that the lubricant can effectively cover both bearings. For example, when grease lubrication is used, the oil inlet and outlet should be located on both sides of the bearing, so that the fresh lubricant first reaches the cylindrical roller bearing that bears the main load, and then flows through the ball bearing to be discharged.

From the perspective of maintenance, the locating end can be set at the drive end or non-drive end of the motor. Considering that there is a certain gap between the outer ring of the ball bearing and the bearing seat, it is easy to disassemble, so it is more convenient to place it on the outside.

In short, when selecting the bearing configuration for the motor shaft system, in addition to considering the bearing's load-bearing capacity, it is also necessary to comprehensively consider factors such as lubrication, maintenance, installation and disassembly to ensure the optimal operating state of the motor.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next The Testing and Inspection Center of ZYS was awarded the Defense Industry Accreditation Committee (DIAC) Laboratory

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.