LASER DRILLING DRILLOPTIMIZER FOR GALVO SCANNER SYSTEMS

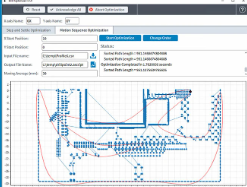

Aerotech Inc. a Pittsburgh, Pennsylvania-based supplier of precision motion control and automation, released its DrillOptimizer, an advanced AeroScriptPlus feature for galvo scanner systems. Designed for equipment manufacturers using laser drilling with high-dynamic point-to-point motion, DrillOptimizer tackles the complex challenge of optimizing step and settle motion for thousands to millions of hole locations, minimizing overall drilling cycle time and maximizing galvo scanner hardware performance.

“Optimizing high-dynamic point-to-point motion for laser drilling applications with varying hole distances has long been a demanding task,” says Aerotech Product Manager Bryan Germann. “We created DrillOptimizer so our customers can save development time and increase throughput without sacrificing on precision.”

DrillOptimizer works in two key ways:

● Motion Sequence Optimization: DrillOptimizer intelligently determines the most efficient path through a pattern of holes, whether within a single scanner field of view (FOV) or when combined with a servo stage system using Infinite Field of View (IFOV). This path optimization directly minimizes the overall cycle time by ensuring the shortest travel distance for the scanner.

● Step and Settle Optimization: DrillOptimizer enables optimal controller parameters to be used for any specific step distance without the scanner leaving the user-defined settle window. By identifying the ideal parameters for each move based on the user-specified settle window and laser-on time, settling move delays are eliminated – allowing the laser to fire with zero delay if the scanner remains within the settle window.

Key benefits include:

Minimized cycle time through optimized motion paths

Maximized galvo scanner hardware performance for every move

Elimination of move delay for laser firing

Guaranteed precision even for large-scale processing

Rapid process development with an intuitive Windows user interface

Seamless integration into custom machine HMIs via a .NET DLL

Production-scale performance with minimal setup

Compatibility with Aerotech’s AGV galvo laser scan head products (AGV-HPO and AGV-XPO)

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ATC Provides Sensor Solution for Remote Process Monitoring

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.