New Needle Roller Pressbearings from QBC Are Self-Aligning

Garden City Park, New York - New series of inch and metric needle roller pressbearings from Quality Bearings & Components - QBC are self-clinching and self-aligning and are designed for high-speed, high-load applications. These pressbearings are identified as the BDNRSS-... Series in inch and BDNRSSM... Series in metric. They are made to fit shafts ranging from .1247" to .6245" in diameter (3.992 mm to 17.989 mm ). The overall diameter of the knurled flanges range from .55". to 1.30" (17 mm to 33 mm). Installation is simple and quick without the use of mounting blocks. Operating temperatures range from -22°F to +248°F (-30°C to +120°C).

• Drawn Cup Needle Roller Bearing

• Carbon Steel Retainer, Black Oxide Finish

Features:

• Simple quick press-fit installation • Self-aligning to ±5°

• High-speed, high-load • No precision holes required

• Major assembly and production savings

Operating Temperature:

-22°F to +248°F

NOTE: Hardened steel shaft required

INSTALLATION:

1. Punch or drill and ream a hole of diameter A in panel as specified in the Design Parameters table.

DO NOT DEBURR OR BREAK EDGE OF HOLE.

2. Place bearing assembly in hole. The slight interference fit assures centering the assembly in the mounting hole.

3. Using an anvil with diameter N, a minimum depth of O and a punch diameter of P, press the bearing assembly into the panel by constantly applying a force of F, per the table, until the assembly is flush with the panel surface.

DO NOT USE HAMMER BLOWS!

SHAFT RECOMMENDATIONS:

Shafts should be hardened to Rc 58 to 64 with 16 µin. finish. Shaft ends should have radii or be chamfered.

INSTALLATION NOTES:

1. The punch must be relieved to accommodate protruding insert.

2. DO NOT PRESS BEARING ON INSERT!

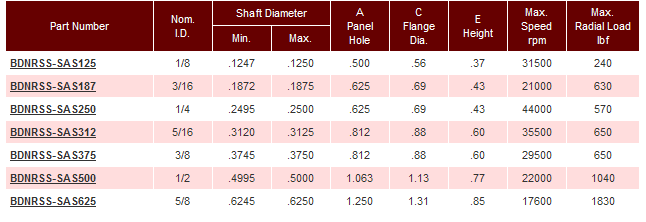

DESIGN PARAMETERS

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.