Technical Problem

The drivetrain team faced an important technical challenge in designing an appropriate gear train that will be used when they transition to hub motors. Hub motors refer to electric motors being mounted within each wheel assembly, and the motors provide drive to the vehicle’s hubs via a gear train, avoiding the conventional drivetrain setup, which involves driveshafts.

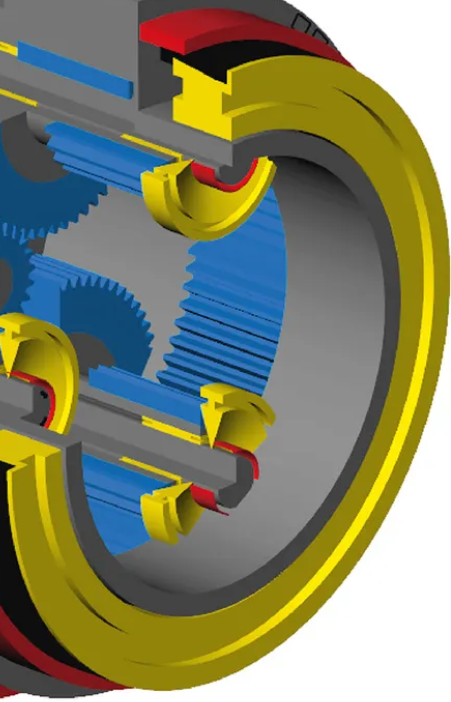

With the electric motor and gear train being constrained to fit within the ten-inch magnesium wheels that they currently use, a compound planetary gear train was required and modeled within KISSsoft, as shown in Figure 1. Due to each planet gear consisting of two stages that are constrained in terms of the center distance for each stage, the macrogeometry tool within KISSsoft allowed them to obtain appropriate gear sizes according to the ISO 6336 standard whilst meeting our desired gear ratio. By defining the required safety factors followed by the specific conditions, the macrogeometry tool provided ear sizes that minimized and balanced the specific sliding of the gear mesh and provided hunting tooth ratios to improve wear distribution and minimize gear vibration. For their first electric vehicle entry last year, the drivetrain sub-team designed a custom planetary gearbox using KISSsoft. Following this design, they had a specific oil supplied by one of their sponsors in terms of yellow metal protection and viscosity. For the design of this new gear train, they wanted to incorporate the properties of this oil into the gear calculations. Within KISSsoft, they were able to add their own oil data into the software through the “own input” function which allowed them to alter the gear design to ensure their contact, bending and scuffing safety factors were met. Figure 2 shows the list of gear sizes obtained for the first stage of the planetary gear train.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.