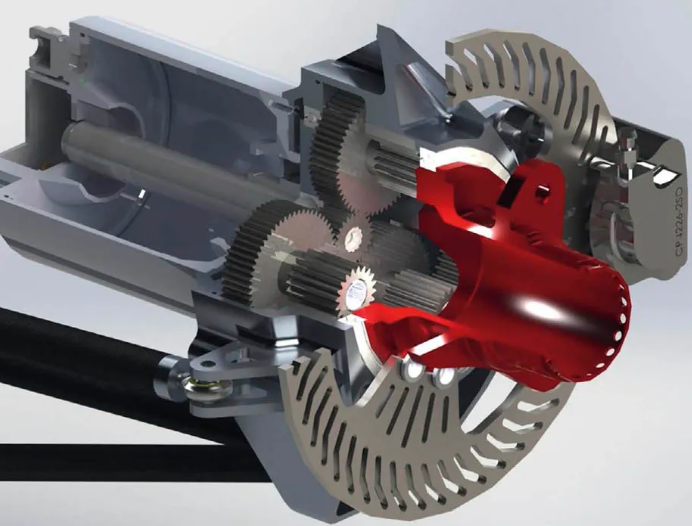

Full wheel assembly model within SolidWorks

Figure 3—Full wheel assembly model within SolidWorks.

Another major advantage of modeling the whole system accurately within KISSsoft was the ability to apply tip and root relief to the gear profile design based on shaft deflection under loading. Using the microgeometry tool, tip and root relief were applied to the gear profile, which removed contact shocks as shown .

Tip and root relief added to remove contact shocks (circled in red).

Being able to implement tip and root relief into the gear design within KISSsoft is advantageous for them based on their manufacturing capabilities which are restricted to wire-EDM. Given their limitation to wire-EDM for manufacturing, they heavily depend on the accuracy of the gear involute model. KISSsoft’s capability to provide precise DXF files of the involute profile, including flank modifications, allows them to confidently send their designs for manufacture. This has been proven by the successful implementation of their first planetary gearbox in their electric vehicle. The support provided by KISSsoft had been crucial for the team to design highly refined gear train solutions.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.