Closed Loop as Solution

If, however, the manufactured and measured gear geometry could be looped back into the original KISSsoft gear design and combined with the designed gear to create a digital twin of the manufactured gear(s), then this twin—or these twins—could be subjected to the same calculations. And the resulting performance characteristics, e.g., contact pressure, may be compared to those of the designed gear. Strength rating methods, e.g., ISO 6336, would then allow for the calculation of gear strength of the manufactured gear and a degradation may be assessed by a gear designer familiar with the requirements. A decision, whether a batch of gears having a geometric deviation needs to be scrapped, is then based on relevant performance characteristics (strength, lifetime, reliability, scuffing safety, etc.), not only on a gear quality number.

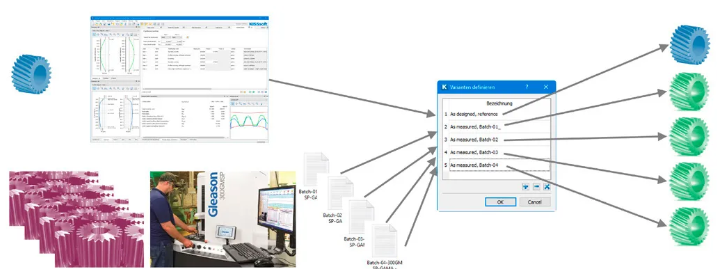

The calculation of the above-mentioned performance parameters of the designed gear as the reference and of several gears or batches of gears as manufactured and measured is done in KISSsoft through variants of the geometry. This means that simultaneously, several gears are defined in one calculation. All have the same gear macro and micro geometry, but each has a different amount of deviation from the reference gear (of course, the reference gear has zero deviation from itself and is variant No. 1), as measured. This means that in a single calculation file, the reference and as many digital twins as required are managed.

The reference design and the digital twins are then subjected to an LTCA. Transmission error, contact stress levels or contact pattern shape and position of the digital twins are then compared to the results of the designed gear. If deviations in the performance parameters are within acceptable limits, the gear or batch of gears is approved. If deviations are too high, the gear or batch of gears is rejected. With this approach, quality control is far more target-oriented compared to using only a gear quality number. It also requires more experience to assess the performance characteristics.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.