Schaeffler Offers Compact FAG Wheel Bearings

This has resulted in a bearing module that is lighter and can be mounted clearance free.

Driving characteristics are therefore improved and automotive manufacturers benefit from a simple mounting process and the associated cost reductions.

The new FAG wheel bearing with spur-gear teeth is better equipped to deal with the loads that occur during vehicle operation.

The spur-gear teeth ensure positive connection between the wheel bearing carrier and the input shaft, which simplifies mounting.

The self-centring axial-gear teeth are placed on the axle journal and fixed in place using a central screw.

Unlike radial-gear teeth, this mounting procedure does not require significant force.

The bearing remains clearance free but securely held in place during vehicle operation.

Having four lighter wheel bearings on the vehicle reduces the unsprung masses, which improves the driving characteristics and contributes to a reduction in CO2 emissions.

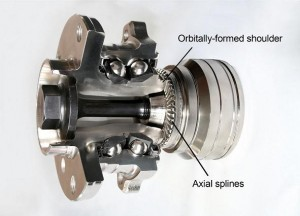

The economical production of the FAG wheel bearing was made possible by the use of an orbitally formed shoulder as the carrier of the gear teeth.

The spur-gear teeth are applied onto the orbitally formed shoulder by high-precision cold forming.

This has resulted in a bearing module that is lighter and can be mounted clearance free.

Driving characteristics are therefore improved and automotive manufacturers benefit from a simple mounting process and the associated cost reductions.

The new FAG wheel bearing with spur-gear teeth is better equipped to deal with the loads that occur during vehicle operation.

The spur-gear teeth ensure positive connection between the wheel bearing carrier and the input shaft, which simplifies mounting.

The self-centring axial-gear teeth are placed on the axle journal and fixed in place using a central screw.

Unlike radial-gear teeth, this mounting procedure does not require significant force.

The bearing remains clearance free but securely held in place during vehicle operation.

Having four lighter wheel bearings on the vehicle reduces the unsprung masses, which improves the driving characteristics and contributes to a reduction in CO2 emissions.

The economical production of the FAG wheel bearing was made possible by the use of an orbitally formed shoulder as the carrier of the gear teeth.

The spur-gear teeth are applied onto the orbitally formed shoulder by high-precision cold forming.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next SKF Monitor Detects Early Damage to Wheel Bearings (Pic)

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.