Schaeffler Differential Holds Promise for OEMs

Schaeffler’s spur differential could help OEMs to make significant weight savings

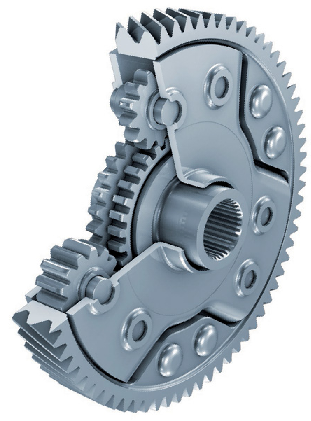

He added that this is because the decision to base the differential on spur, rather than bevel, gears had some significant implications on the choice of processes used to manufacture it. It was possible, for example, for the planetary gears to be pressed, rather than forged, while the housing of the differential could be manufactured from deep-drawn sheet metal parts.

Presently, only the sun gears in the differential are still forged parts, but Biermann said the company is working on developing technology so that, in the future, those could be cold formed too.

’Unlike a traditional bevel gear differential where the housing is normally cast and the inner gearings are forged, the new differential can be produced cost effectively in high volumes, for the most part using pressing and cold-forming manufacturing techniques, which are more energy-efficient processes,’ he said.

The company has designed two types of the new differential a symmetrical and an asymmetrical version after the designers recognised that the asymmetric design would be particularly useful in high-volume applications where car manufacturers need to save as much space in the vehicle drivetrain as possible.

Although Biermann admitted that the symmetrical version of the spur gear differential is not an entirely new idea a similar design was proposed by US-based Audel and Company as early as 1911 the Schaeffler differential with asymmetrically arranged planets and straight-cut gear teeth is most certainly a novel development.

However, as the asymmetric design demands different-sized sun and planetary gears and even different-sized planetary carriers, while the symmetric design does not, Biermann added that the cost of manufacturing it is likely to be higher than its symmetric brother.

Despite the cost implications, the design envelope of both new differentials is considerably smaller than earlier designs, in part because the support bearings of the differential are on a plane with the main bearing of the output shafts.

’In the case of the asymmetrical design, the differential gearing even remains completely within the design space width of the final drive gear, meaning we can free up 70 per cent axial space in the gearbox,’ he said.

The short bearing support found on the new differential design also brings its own advantages. Biermann said that, because of where the bearings are located on the new differential, the radial forces at the bearings that support the differential are nearly equal.

Schaeffler’s spur differential could help OEMs to make significant weight savings

He added that this is because the decision to base the differential on spur, rather than bevel, gears had some significant implications on the choice of processes used to manufacture it. It was possible, for example, for the planetary gears to be pressed, rather than forged, while the housing of the differential could be manufactured from deep-drawn sheet metal parts.

Presently, only the sun gears in the differential are still forged parts, but Biermann said the company is working on developing technology so that, in the future, those could be cold formed too.

’Unlike a traditional bevel gear differential where the housing is normally cast and the inner gearings are forged, the new differential can be produced cost effectively in high volumes, for the most part using pressing and cold-forming manufacturing techniques, which are more energy-efficient processes,’ he said.

The company has designed two types of the new differential a symmetrical and an asymmetrical version after the designers recognised that the asymmetric design would be particularly useful in high-volume applications where car manufacturers need to save as much space in the vehicle drivetrain as possible.

Although Biermann admitted that the symmetrical version of the spur gear differential is not an entirely new idea a similar design was proposed by US-based Audel and Company as early as 1911 the Schaeffler differential with asymmetrically arranged planets and straight-cut gear teeth is most certainly a novel development.

However, as the asymmetric design demands different-sized sun and planetary gears and even different-sized planetary carriers, while the symmetric design does not, Biermann added that the cost of manufacturing it is likely to be higher than its symmetric brother.

Despite the cost implications, the design envelope of both new differentials is considerably smaller than earlier designs, in part because the support bearings of the differential are on a plane with the main bearing of the output shafts.

’In the case of the asymmetrical design, the differential gearing even remains completely within the design space width of the final drive gear, meaning we can free up 70 per cent axial space in the gearbox,’ he said.

The short bearing support found on the new differential design also brings its own advantages. Biermann said that, because of where the bearings are located on the new differential, the radial forces at the bearings that support the differential are nearly equal.

It is hoped that the differential will make its way into production vehicles by 2016

On a traditional bevel gear differential, however, it is a different story. There, the bearings support the differential at different distances from the ring gear that drives them, with the result that one will experience higher stresses than the other. On the new spur gear design, since both bearings are at the same distance from the ring gear, they will wear equally.

However, as a standalone entity, the new differential has a lower stiffness in comparison with a bevel gear differential, because it enabled the Schaeffler engineers to redesign the complete transmission system including the bearings and the differential housing. The overall stiffness of the complete system is actually greater, with the result that the complete assembly produces less noise. Biermann said that, at the present time, Schaeffler is building prototypes of both symmetric and asymmetric differentials for several car manufacturers. This will be followed by an intensive design optimisation stage, after which Schaeffler will decide whether to move into series production of such units.

Presently, it is too early in the development cycle for the company to comment on what new model of car the new differential might be found on first. Nevertheless, having already received several orders for prototypes, Biermann is hopeful that the differential will make its way into production vehicles by 2016.

’Ultimately, the lightweight differential could save valuable space that might be used for either larger dual clutches or transfer gearboxes, as well as making room for electrical components on hybrid electric vehicles,’ he said.

It is hoped that the differential will make its way into production vehicles by 2016

On a traditional bevel gear differential, however, it is a different story. There, the bearings support the differential at different distances from the ring gear that drives them, with the result that one will experience higher stresses than the other. On the new spur gear design, since both bearings are at the same distance from the ring gear, they will wear equally.

However, as a standalone entity, the new differential has a lower stiffness in comparison with a bevel gear differential, because it enabled the Schaeffler engineers to redesign the complete transmission system including the bearings and the differential housing. The overall stiffness of the complete system is actually greater, with the result that the complete assembly produces less noise. Biermann said that, at the present time, Schaeffler is building prototypes of both symmetric and asymmetric differentials for several car manufacturers. This will be followed by an intensive design optimisation stage, after which Schaeffler will decide whether to move into series production of such units.

Presently, it is too early in the development cycle for the company to comment on what new model of car the new differential might be found on first. Nevertheless, having already received several orders for prototypes, Biermann is hopeful that the differential will make its way into production vehicles by 2016.

’Ultimately, the lightweight differential could save valuable space that might be used for either larger dual clutches or transfer gearboxes, as well as making room for electrical components on hybrid electric vehicles,’ he said.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Timken Completes Philadelphia Gear Acquisition

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.