Development of “Parallel link High speed Angle Control Equipment” for High-speed, High-precision Positioning from NTN

Resource from: NTN Likes:3056

Jan 11,2012

(January 11, 2012)

NTN Corporation (hereafter, NTN) has developed the “Parallel link High speed Angle Control Equipment”, a compact device that allows high-speed, high-precision positioning over a wide range of moving angles.

Angle positioning control mechanisms usually consist of a parallel link mechanism*1 or a serial link mechanism*2. There have been issues associated with these mechanisms, including the larger size of devices when using parallel link mechanisms, or the lower positioning speed when using serial link mechanisms due to the weight of the moving parts.

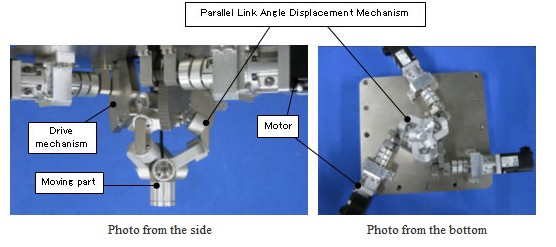

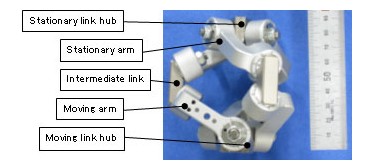

The “Parallel link High speed Angle Control Equipment” developed by NTN employs a proprietary parallel link mechanism*3. This allows the associated device to be designed smaller and move over a wide range of angles. A newly developed drive mechanism also allows coordinated control of the angle of each of the three stationary arms, which ensures high-speed positioning, even when compact motors are used. A control method that allows minor reciprocal interference between the three arms serves to cancel out play (backlash) between rotating parts and increase positioning precision tenfold from ± 0.5 mm to ± 0.05 mm.

NTN will be marketing the newly developed product as a device that helps to improve productivity of automated production equipment that requires high-speed, high-precision positioning over a wide range of moving angles, in a space-efficient package.

*1 A mechanism that supports a single tip with multiple arms, where each arm is connected in parallel.

*2 A link mechanism that connects multiple links in series, which is often used in industrial robots (jointed-arm robots).

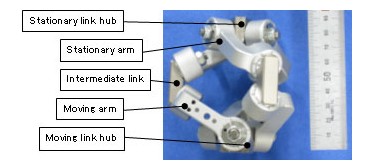

*3 Mechanism comprising of three sets of similar link systems between the moving and stationary link hubs. Each link system consists of a rotating L-shaped arm attached to the outer circumference of the moving and stationary link hubs, and a rotatably connected intermediate link connecting the axis of rotation of the end of each hub in a single location.

[Features] Allows free tracing of operating paths utilizing its high-speed, high-precision features.

(1) High-speed : positioning at 10-points/second

More than 20% faster when compared to a serial link mechanism (when attached with an 800 g load)

(2) High-precision : tenfold improvement in repeated positioning precision (compared to conventional NTN product)

± 0.5 mm ⇒ ± 0.05 mm (positioned 70 mm from the center of rotation)

(3) Compact and wide range of angles : allows a compact size that is 1/5 that of ordinary link mechanisms

A proprietary parallel link mechanism delivers 360° angle of rotation, and 90° angle of operation

[Applications]

Equipment and other devices for the application of grease or adhesives, painting or parts handling

[Inquiries about this release]

Product Innovation & Intellectual Property Strategy Department Tel. +81-6-6449-3602

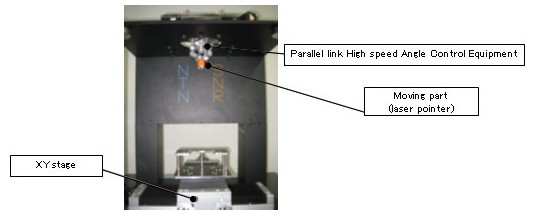

[Product Photo]

Parallel link High speed Angle Control Equipment

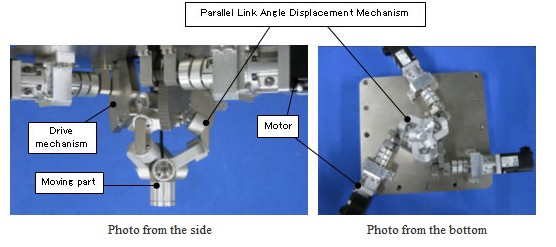

[Parallel Link Angle Displacement Mechanism]

[Parallel Link Angle Displacement Mechanism]

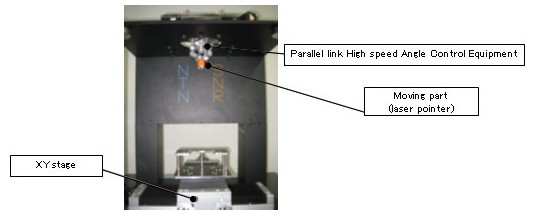

[Example of Application]

[Example of Application]

(NTN)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

[Parallel Link Angle Displacement Mechanism]

[Parallel Link Angle Displacement Mechanism]

[Example of Application]

[Example of Application]