Development of "Multi Layer BEARPHITE"

Resource from: NTN Corporation Likes:256

Sep 24,2012

[World first! Double-molding method used for oil-impregnated sintered bearings with high-strength and outstanding wear-resistance]

NTN Corporation (hereafter, NTN) has developed the “Multi Layer BEARPHITE” that offers high strength and outstanding wear-resistance using a newly developed sintering molding method.

Oil-impregnated sintered bearings are widely used as sliding bearings under light-load conditions such as small motors, however have been used in parts requiring high-loads, such as the joints of construction machinery. Bearings for high-load applications require steel materials with excellent wear-resistance machined with special heat treatment such as carburization for increased strength, followed by a cutting process for the inner diameter surface. Compared to bearings for light-load applications that are manufactured using only a pressing process, the additional work processes required for bearings for high-load applications has long presented a challenge.

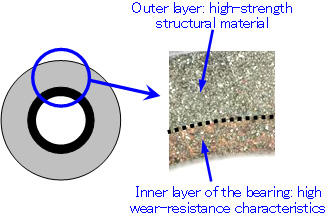

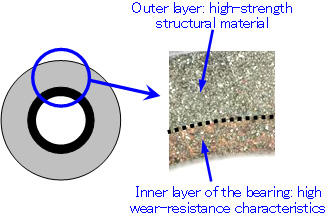

The newly developed “Multi Layer BEARPHITE” is an oil-impregnated sintered bearing that features the internal layers of the bearing made of a material with a high-strength and outstanding wear-resistance, and the outer layers made of a high-strength structural material, in what is the world's first double-molding method*1. The use of high-strength structural material for the outer layers of the bearing eliminate the need for special heat treatment, and greater dimensional precision with the sizing*2 process using a press means conventional cutting process is no longer required.

NTN has already started to propose the developed product to construction machinery manufacturers, and will soon start releasing the new bearing globally. The double-molding technology developed for this product will be applied to gears and other sintered machinery parts in addition to oil-impregnated sintered bearings, with plans for a greater level of use in industrial machinery and automotive markets.

*1 Double-molding method : a molding process that casts two dissimilar materials to form a single object.

*2 Sizing : a process that machines inner and outer diameter dimensions to the required precision using a shaped press.

[ Features ]

The double-molding method, which is used to cast two dissimilar materials into a single object, has been used for high-strength and outstanding wear-resistance

(1) Radial crushing strength of 500MPa or more, oil content of 17 vol% or more

→ Optimized material and sintering conditions for the required strength and oil content without any special heat treatment

(2) Variation in inner and outer diameter dimensional precision of 50 μm or less

→ Sizing process used to maintain precision, eliminating the need for the cutting process

(values for (1) and (2) above obtained from test results of a bearing with dimensionsφ35×φ45×35)

[ Product Photo ]

[ Structure ]

[ Structure ]

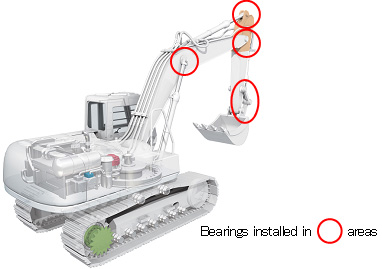

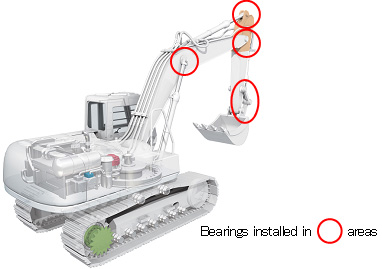

[ Example of applications ] Joints of hydraulic excavators

[ Example of applications ] Joints of hydraulic excavators

(NTN Corporation)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

[ Structure ]

[ Structure ]

[ Example of applications ] Joints of hydraulic excavators

[ Example of applications ] Joints of hydraulic excavators