Measuring the performance of extreme-pressure gear oil

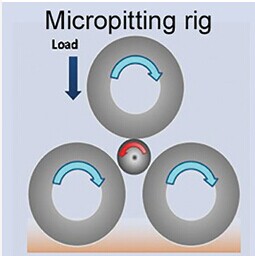

The MPR layout surrounds a test roller (center) with three load rollers.

In the wind industry, extreme pressure (EP) gear oil, also called anti-scuff oil, has two jobs that are equally important. For one, the oil is expected to provide a high level of protection for a costly turbine component, and second, it has to last for five or more years. The need to meet both criteria and exceed other performance requirements means oil formulation is critical.

EP additives at a glance

There are two major types of EP additive systems in use in wind-turbine gear oils: ashless and organo metallic. Exploring what happens to EP gear oils over time reveals the different roles that additives play. Weighing this performance also helps determine the best formulation for component needs and determine how to maintain EP gear oil for maximum results. This is especially important when battling micropitting, the predominant wear mode in gearboxes.

EP additives are sacrificial, yet some are formulated to last longer than others. To start, the additives use temperature-activated polar molecules that provide a chemical barrier against friction and wear. Under extreme pressure and temperature, EP additives migrate from the fluid to the metal surface, forming a strong chemical bond that results in a protective film or tribolayer. The additives are effectively consumed as they attach themselves to metal surfaces. This consumption can be verified by lower elemental counts in lab analyses over time. Consult a lubricant supplier for minimum additive levels and rates of usage.

Test_Rollers-actual

The MPR layout surrounds a test roller (center) with three load rollers.

In the wind industry, extreme pressure (EP) gear oil, also called anti-scuff oil, has two jobs that are equally important. For one, the oil is expected to provide a high level of protection for a costly turbine component, and second, it has to last for five or more years. The need to meet both criteria and exceed other performance requirements means oil formulation is critical.

EP additives at a glance

There are two major types of EP additive systems in use in wind-turbine gear oils: ashless and organo metallic. Exploring what happens to EP gear oils over time reveals the different roles that additives play. Weighing this performance also helps determine the best formulation for component needs and determine how to maintain EP gear oil for maximum results. This is especially important when battling micropitting, the predominant wear mode in gearboxes.

EP additives are sacrificial, yet some are formulated to last longer than others. To start, the additives use temperature-activated polar molecules that provide a chemical barrier against friction and wear. Under extreme pressure and temperature, EP additives migrate from the fluid to the metal surface, forming a strong chemical bond that results in a protective film or tribolayer. The additives are effectively consumed as they attach themselves to metal surfaces. This consumption can be verified by lower elemental counts in lab analyses over time. Consult a lubricant supplier for minimum additive levels and rates of usage.

Test_Rollers-actual

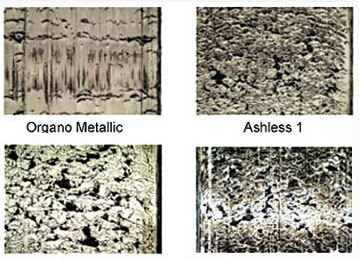

Actual test rollers. Microphotographs of the MPR test rig show the remaining additive systems on each surface.

Predicting performance

EP gear oil’s performance can be predicted based upon its specific additives. The ultimate goal is to optimize a set of molecular compounds that achieves better performance as a package than the compounds do individually.

A micropitting rig (MPR) is used to generate data which helps understand the impact of this process on gears and bearings. The image at the top-right of the article shows the layout of an MPR with the test roller in the center of the three load rollers. The Endurance Test Protocol developed by Powertrib Ltd. measures micropitting performance similar to the FZG FVA 54, but with improved repeatability, control, and a reduced evaluation time. FZG is a type of gear test and FVA 54 is the accompanying test work sheet. Primary results are from the test roller wear (weight) measurements. With three fully formulated oils, one organo metallic and two ashless products, different optimized compounds produce varying levels of performance.

How the EP additives stack up in MPR endurance testing (below) shows the final measurements taken after an endurance test with respect to coefficient of friction, vibration signal, and roller wear (in terms of weight loss). Microphotographs of the actual test rollers (up left) depict the remaining additive systems on the surfaces, along with the pitting that ensued during the test.

Actual test rollers. Microphotographs of the MPR test rig show the remaining additive systems on each surface.

Predicting performance

EP gear oil’s performance can be predicted based upon its specific additives. The ultimate goal is to optimize a set of molecular compounds that achieves better performance as a package than the compounds do individually.

A micropitting rig (MPR) is used to generate data which helps understand the impact of this process on gears and bearings. The image at the top-right of the article shows the layout of an MPR with the test roller in the center of the three load rollers. The Endurance Test Protocol developed by Powertrib Ltd. measures micropitting performance similar to the FZG FVA 54, but with improved repeatability, control, and a reduced evaluation time. FZG is a type of gear test and FVA 54 is the accompanying test work sheet. Primary results are from the test roller wear (weight) measurements. With three fully formulated oils, one organo metallic and two ashless products, different optimized compounds produce varying levels of performance.

How the EP additives stack up in MPR endurance testing (below) shows the final measurements taken after an endurance test with respect to coefficient of friction, vibration signal, and roller wear (in terms of weight loss). Microphotographs of the actual test rollers (up left) depict the remaining additive systems on the surfaces, along with the pitting that ensued during the test.

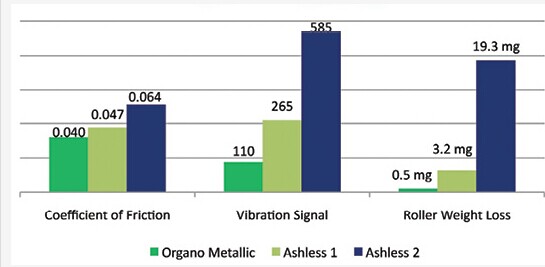

How the EP additives stack up in MPR endurance testing. The final measurements after completing the MPR endurance test are for the coefficient of friction, vibration signal, and roller wear. As you might anticipate, lower coefficients of friction generate less wear so lower vibration signals come from a more uniform surface. This reduced friction and wear ultimately extends the life of critical bearings and gears.

Additive reserve strength

EP additives will be consumed as they provide protection to the metal surfaces. They can also be impacted by contaminants and filtration. Each fluid is different in terms of how much reserve capability it has to provide protection over time and additive usage.

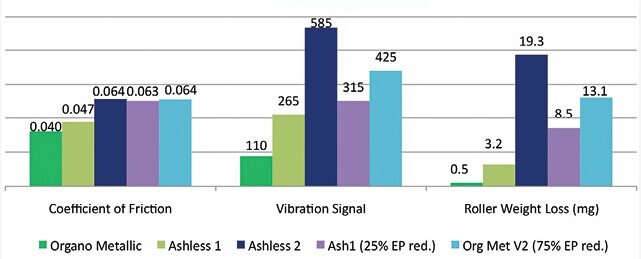

Additive performance in MPR endurance testing (below) illustrates the measurement of the organo metallic formula in an extreme case of heavily used oil with 75% additive depletion. This is a level below the condemning limits set forth by the formulator. Virgin test results have been left in for comparison. As anticipated, there was a decline in performance, but perhaps not to the extent one might think. It is interesting to note that the aged oil (fourth bar in each group) still had better performance than the third product in its virgin state.

How the EP additives stack up in MPR endurance testing. The final measurements after completing the MPR endurance test are for the coefficient of friction, vibration signal, and roller wear. As you might anticipate, lower coefficients of friction generate less wear so lower vibration signals come from a more uniform surface. This reduced friction and wear ultimately extends the life of critical bearings and gears.

Additive reserve strength

EP additives will be consumed as they provide protection to the metal surfaces. They can also be impacted by contaminants and filtration. Each fluid is different in terms of how much reserve capability it has to provide protection over time and additive usage.

Additive performance in MPR endurance testing (below) illustrates the measurement of the organo metallic formula in an extreme case of heavily used oil with 75% additive depletion. This is a level below the condemning limits set forth by the formulator. Virgin test results have been left in for comparison. As anticipated, there was a decline in performance, but perhaps not to the extent one might think. It is interesting to note that the aged oil (fourth bar in each group) still had better performance than the third product in its virgin state.

Additive performance in MPR endurance testing. The results show (lower is better) reduced performance measurements for the organo metallic formula in heavily used oil with 75% additive depletion. However, the worn oil in the right two categories still out performed the Ashless 2 additives in each group.

Formulation matters

While all EP oils contain similar classes of additive chemistry, there are additional developments available that improve wear protection. In addition, the amount of reserve capability of those fully formulated oils varies. This variation can have a long-lasting impact on critical load bearing surfaces and on gearbox life.

Additive performance in MPR endurance testing. The results show (lower is better) reduced performance measurements for the organo metallic formula in heavily used oil with 75% additive depletion. However, the worn oil in the right two categories still out performed the Ashless 2 additives in each group.

Formulation matters

While all EP oils contain similar classes of additive chemistry, there are additional developments available that improve wear protection. In addition, the amount of reserve capability of those fully formulated oils varies. This variation can have a long-lasting impact on critical load bearing surfaces and on gearbox life.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Vestas gets 33 MW order in Finland

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.