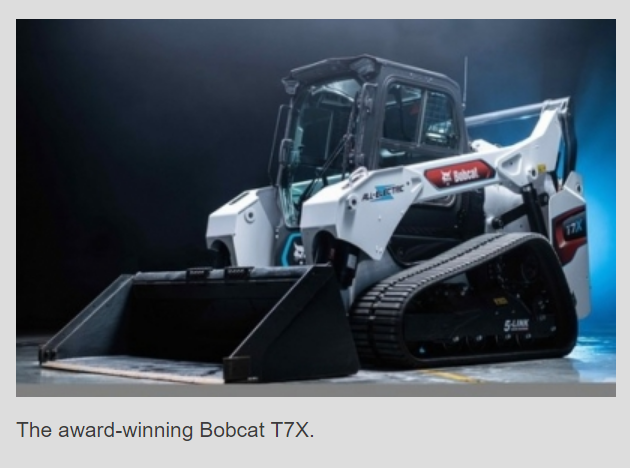

Moog Partners with Doosan Bobcat on All-Electric Compact Track Loader

Moog Inc. recently announced that the company is providing Doosan Bobcat with its intelligent machine electrification system to help Bobcat design and build the world’s first all-electric compact track loader: the award-winning Bobcat T7X, which does not use hydraulic parts or oil. The T7X is a zero-emission and all-electric machine with the power and performance of a diesel hydraulic machine but without the noise, emissions, and hydraulic leaks.

Moog’s intelligent machine electrification system consists of Moog’s integrated software framework, a sophisticated electric machine controller, lift and tilt electric cylinders, electric traction motors, and power electronics. With the help of Moog’s system, the T7X is a major step forward for the productivity, safety, and sustainability of construction machinery.

“Bobcat had a vision for an all-electric machine,” said Joe Baldi, director of strategy & partnerships for Moog. “Our conversation began with Moog’s all-electric actuators, but ultimately our talks led to the intelligent machine electrification system. Working in partnership with Bobcat, we were able to bring that all-electric vision to life in six months.”

Moog has a long history of converting hydraulic systems to electric in industries including aerospace, defense, and industrial machinery as well as in applications such as simulators for air, sea, and land vehicles. Leveraging this expertise, Moog’s intelligent machine electrification system helps the T7X control the motion of the tracks, as well as lift and tilt functions with industry-leading efficiency to enable a powerful zero-emission machine with significantly increased run time and reduced maintenance costs.

“To describe our contribution to the T7X in anatomical terms,” added Baldi, “we supplied the part of the brain that controls motion; the nervous system helping to intelligently coordinate actions, power, and sensor information; and the muscles, which are the all-electric actuators and motors.”

Production-ready solution

On January 4, 2022, in Las Vegas at CES 2022, Doosan Bobcat announced that Sunbelt Rentals will invest in a fleet of the all-electric T7X compact track loaders. The all-electric machines will be co-branded by Bobcat and Sunbelt and made available in 2022.

Moog construction

Moog Inc. has launched a new venture called Moog construction. “Our focus is accelerating electrification, automation, and connectivity by enabling the world’s safest, most sustainable, and most productive machines,” said Joe Alfieri, vice president and general manager for Moog construction.

Moog construction is bringing the intelligent machine electrification system to market for customers looking to create zero-emission, connected, and more automated machines.

By seamlessly integrating multiple subsystems including power management, motion control, connectivity, and automation, Moog enables customers to develop their own differentiated offerings and bring their vision for next-generation machines to life, while decreasing development costs and the time to bring products to market.

“Our vision is to be the leading provider of electrification and automation solutions,” said John Scannell, chairman and CEO of Moog Inc. “This effort brings differentiated technology that will enable the construction industry to move to a more productive, safe, and sustainable future. Moog’s 70 years of experience supporting customers around the world means that we can draw on our existing infrastructure to manufacture, service, and support customers at scale.”

The intelligent machine electrification system is designed to be connected and automation ready. Leveraging Moog’s deep expertise, the system has the sensing and control capabilities needed for automation while the integrated software framework comes with built-in tools to coordinate multiple axes of motion and precisely control torque, velocity, position, and force. This, paired with the system’s connectivity, enables Moog construction customers to develop and deploy valuable automation functionality via software updates more easily and continuously.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next World PM2022 Call for Papers Accepted Until January 19, 2022

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.