Schaeffler electric wheel hub motors go into production; three OEM customers

Schaeffler has begun production of its electric wheel hub motors; three manufacturers of compact municipal vehicles are gearing up to incorporate the motors into their production lines in the coming months.

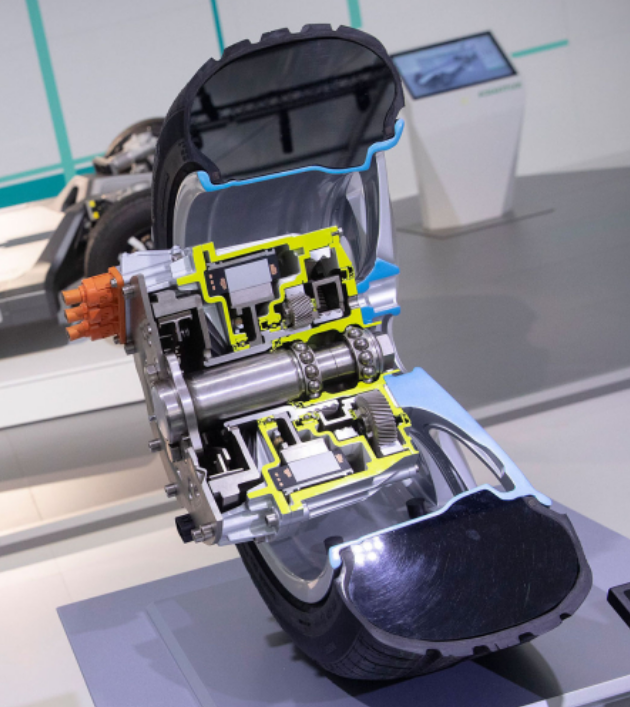

All the components needed for propulsion and braking are integrated directly into the wheel rim, rather than being positioned centrally or mounted on the drive axles. This architecture saves space and makes the vehicles more agile and maneuverable in city traffic.

Utility vehicles powered by these low-noise, fully electric motors are very quiet to operate, resulting in reduced sound pollution in pedestrian areas and on city streets. They can also be operated for extended hours in residential areas because the disturbance to residents is so much less.

One of the first companies to be launching a multifunction vehicle comprising Schaeffler wheel hub motor technology onto the market this year is Jungo. Jungo and Schaeffler have been partnering to tailor the drive technology to the specific everyday requirements of commercial street sweeping.

Schaeffler aims to see its wheel hub motors used in more and more utility and service vehicles in towns and cities, on factory campuses, and at logistics centers, ports, airports, and large parking facilities. These types of vehicles tend to be operated on set routes, so they are a good fit for the fixed ranges and predictable charging times of electric drives. Another key benefit for vehicle operators is that the wheel hub motors have long-life, low-maintenance wheel bearings and gearboxes.

Schaeffler’s fully electric wheel hub motors have an architecture in which the electric motor (stator and rotor), gearbox, and mechanical friction brake are arranged around the wheel bearing inside the rim. This compact design envelope frees up space elsewhere in the vehicle. It also gives vehicle manufacturers greater design freedom, allowing them to develop a wide range of mobility formats, including rolling chassis solutions.

The wheel hub motor, including the gearbox, is very compact, fitting inside a 14-inch rim. The inverter, on the other hand, is not integrated, and can be accommodated anywhere in the vehicle. A single inverter controls one or two wheel hub motors, depending on the use scenario.

The motor’s power output is scalable, depending on the application, ranging from 7 kW to 26 kW (nominal) and peaking at 60 kW for short bursts. The torque generated by the electric motor is transmitted via the gearbox directly to the wheel. This direct transmission reduces energy loss, making the drive highly efficient.

Another key benefit is that torque and direction of rotation are controlled individually for each wheel, resulting in an all-wheel drive vehicle that can handle hills with consummate ease, even in winter road conditions. Schaeffler currently develops wheel hub motors for 48 V and 400 V applications and is exploring the possibility of higher voltages.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next THORDON BEARINGS DELIVERS ROBUST SUPPORT TO WIND POWER-IN-A-BOX TECHNOLOGY

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.