REDEX'S PRELOADED SYSTEMS

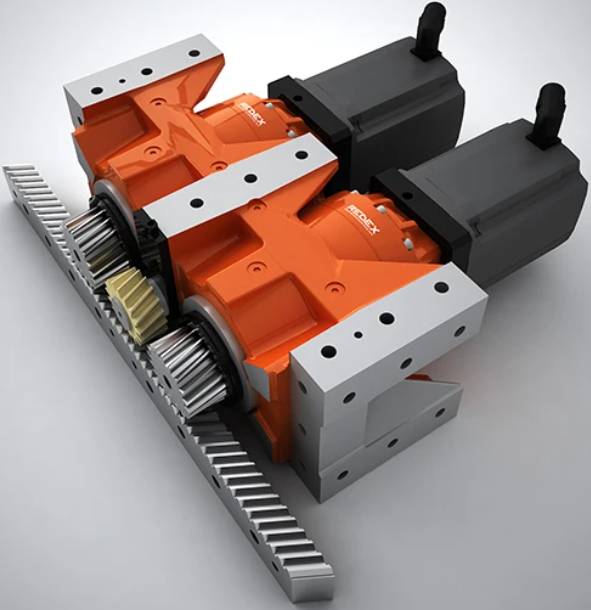

Redex is pleased to announce its patented DualDRIVE and TwinDRIVE preloading technologies now give CNC machine designers several ways to build a zero backlash system.

These approaches leverage Redex modular SRP, DRP, KRP and KRPX Series rack and pinion reducers whose output pinions are preloaded against the rack to eliminate backlash — a longstanding challenge with designs requiring long axis travels and require positioning over the entire length of travel to less than 0.001". Here’s how Redex DualDRIVE and TwinDRIVE preloading technologies work to create a zero-backlash system:

DualDRIVE systems achieve a mechanical preload by torsionally winding one pinion against the other when both pinions are in contact with the same rack. DualDRIVE needs just one motor, and no special controllers are required.

TwinDRIVE technology electrically brakes one pinion against the other — driving — pinion when both pinions are in contact with the same rack. These systems incorporate two motors and gearboxes for use with CNC control.

Redex SRP, DRP, KRP and KRPX Series rack and pinion reducers, together with DualDRIVE or TwinDRIVE technology, let machine designers create zero-backlash preloaded systems that achieve precise positioning and improved stiffness in CNC applications. These reducers feature optimized radial and torsional stiffness, very high linear accuracy, compact sizes and precision geometry for meshing with the rack. They can be implemented in the following ways:

DualDRIVE

Two Right Angle SRP planetary reducers (SRP DualDRIVE Kit)

Two Right Angle KRP planetary reducers (KRP DualDRIVE Kit)

One Right Angle DRP including two planetary reducers in one housing (DualDRIVE)

TwinDRIVE

Two SRP planetary reducers (SRP TwinDRIVE Kit)

Two KRP planetary reducers which is called (KRP TwinDRIVE Kit)

One DRP including two planetary reducers in one housing (TwinDRIVE)

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next OPTIMAL ENGINEERING SYSTEMS' ROTARY STAGES

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.