China Revolutionary Liquid Metal Bearing Ball Tube: Innovation in Materials Science and Engineering

In the context of increasing precision requirements for medical imaging technology, the performance improvement of the tube as a key component has become an important factor in promoting the progress of the industry. Relying on its deep accumulation in material research and precision manufacturing, Dunlee has launched a revolutionary liquid metal bearing tube, which not only breaks through the limitations of traditional design, but also significantly improves the reliability, efficiency and image quality of medical imaging equipment through cross-domain technological innovation.

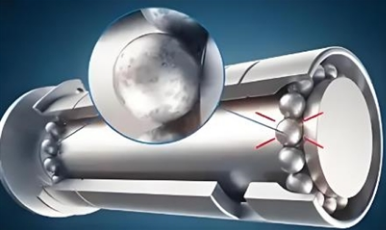

The core of this new tube is the use of special liquid metal alloy materials. Compared with traditional solid lubricants (such as graphite or ceramics), this type of liquid metal exhibits unique fluidity characteristics in microstructure. Take gallium-based alloys as an example. It remains liquid at room temperature and has extremely low viscosity (usually less than 0.1 Pa·s) and high thermal conductivity (about 30 W/m·K). This enables liquid metal to form a uniform lubrication layer on the bearing surface, greatly reducing the friction coefficient between rotating parts to less than 0.001, which is almost two orders of magnitude less than traditional bearings. At the same time, the chemical stability of liquid metal helps prevent oxidation and evaporation, ensuring long-term stable operation in a vacuum environment.

Dangli uses advanced nano-processing technology to create microstructures on the contact surface, enhancing the adhesion and load-bearing capacity of liquid metal. Experiments show that even at up to 200,000 revolutions per minute, the temperature rise of the improved liquid metal bearing is 60% lower than that of the traditional design, the wear is close to zero, and the service life is extended by more than three times. This progress solves the problem of image distortion caused by bearing wear and provides hardware support for long-term high-efficiency imaging.

In order to maximize the advantages of liquid metal bearings, Dangli uses multi-physics field simulation technology to optimize the design of the thermoelectric integrated characteristics of the tube, especially improving the heat dissipation path of the anode target. The good thermal conductivity of liquid metal allows heat to be quickly transferred from the target surface to the bearing part, and through the finely designed cooling system, the heat dissipation efficiency is improved by 40%, ensuring that the tube maintains a stable thermal state during continuous exposure and avoiding X-ray energy distribution deviation.

In addition, Dangli has developed a dynamic balance adjustment technology that controls the rotation eccentricity of the tube within 0.1 microns by real-time monitoring of the bearing vibration frequency and automatically adjusting the rotor weight distribution, far exceeding international standards. This ensures that the tube can still provide a spatial resolution of up to 20 lp/cm during high-speed scanning, which is essential for the detection of early lung lesions and subtle calcifications.

Clinical trials have confirmed that the value of liquid metal bearing tubes has been demonstrated in multiple research centers. For example, in a comparative study at the Mayo Clinic in the United States, the image noise level of CT equipment using this technology in coronary artery CTA examinations was reduced to 8 HU (compared to 15 HU for traditional equipment), and an isotropic resolution of 0.28 mm was achieved, making it possible to assess the risk of plaque rupture of less than 1 mm. In the field of tumor radiotherapy, tubes supported by liquid metal bearings can work continuously for more than 8 hours, and cooperate with CBCT to achieve sub-millimeter-level precise registration of daily radiotherapy target areas, reducing the positioning error from 3 mm to 0.5 mm, greatly improving the accuracy of radiotherapy.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Key Technology Research and Application of Spindle Bearings for Offshore High-Power Wind Turbines from Xinqianglian Bearing passed expert appraisal

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.