About Us

We are one of the leading providers of China exporting industry and a long-time partner of professional dealers.

Started this business in 2009, we are one of the leading providers of China exporting industry and a long-time partner of professional dealers.

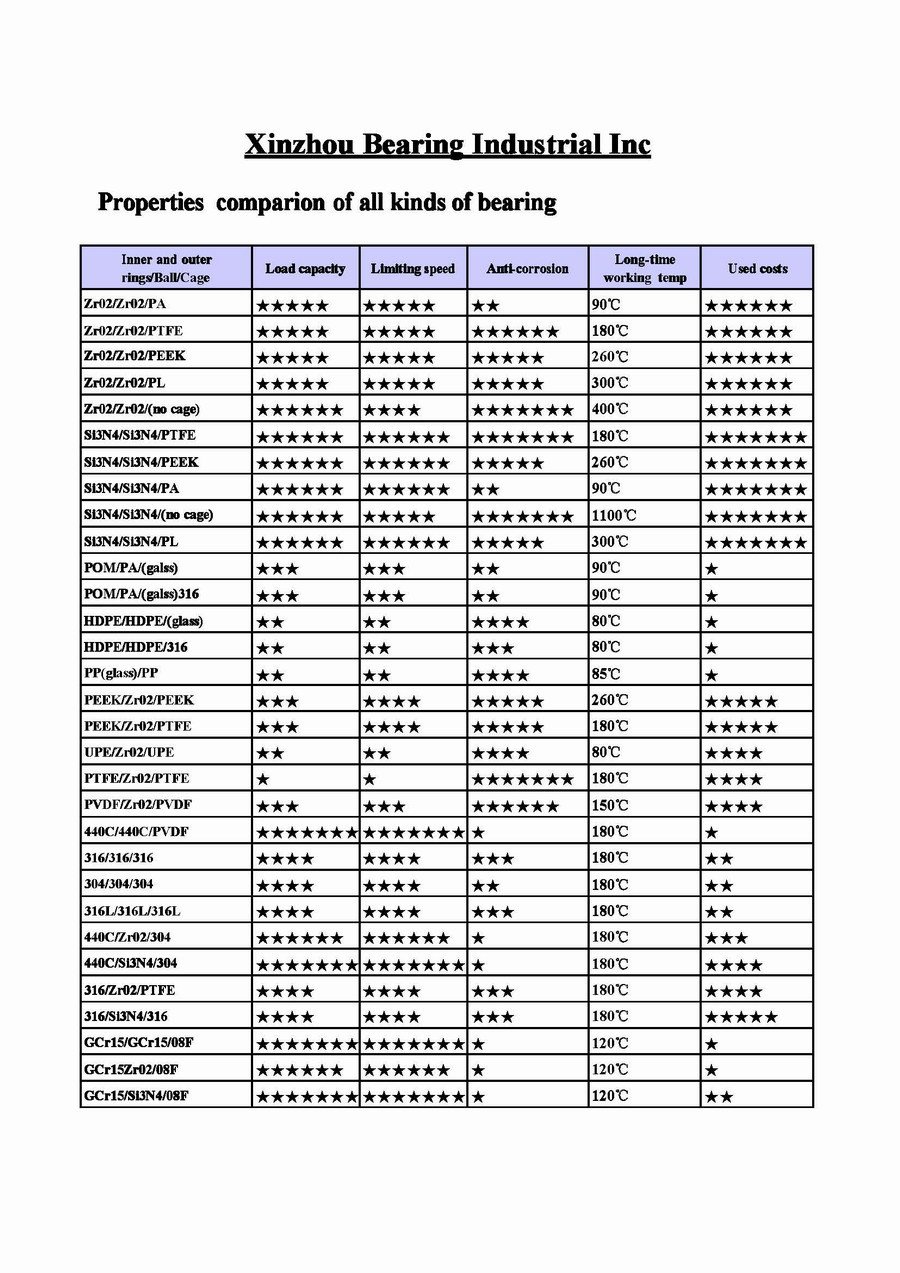

Xinzhou Bearing Industry Inc. is one of the Custom Bearing Manufactures and world wide Distributors of all types of Bearings Including Ball, Roller,Ceramic (Hybrid), Thrust, and Custom Bearings.Specializing in Ball, Needle, and Roller types (Inch and Metric Sizes) made from Ceramic (Si3N4/ZrO2), Stainless (440c/316) or Chrome (52100 steel); Tolerance ABEC1, 3, 5, 7.level.

We work directly with our OEMs and Bearing Distributors. Our engineers can help you with bearing, shaft and housing tolerances as well as semiconductor applications, cryogenic applications, extreme hostile environments, and extreme delta T temperatures environments.

We also stock other manufacturer's bearings. We distribute bearings for extreme high temperature. We can help design/manufacture any bearing with a 2-week turnaround. We are professional in manufacturing and exporting all kind of full ceramic balls,(eg: Si3N4, ZrO2, Al2O3, SIC balls for bearing and other purpose, Full Ceramic Bearing, Ceramic Hybrid Bearing, Stainless Ball Bearing.Chrome steel bearings.

Besides, we are working together with 50 factories in bearing fields. Xinzhou Bearing Industry Inc is a self-management of export company, you don't need to worry about the quality and you can be sure about our service.

Profession is one of the most important characteristics It makes both of the cooperation partners feel at ease. It is a long mission for us to keep and improve it .For our mutual benefits, we should stick to it .The success is just the adding up of several hands .It is the sight we are happy to see.

We stick to our principles and our commitment, we accept any opinions, try to improve us and serve the best. For our customers, we commit to the earliest response, best service and smartest solution.

We would like to establish long-term business-relations with customers all over the world on the basis of sincere-cooperation, equality and mutual benefit. High quality, competitive price, and satisfying service are our promises to our customers.

Like Our Motto is Customer First,Quality Forever.

Any Business visit and negotiation is warmly welcomed.

Contact us

Colin Chen, Sales Manager

Daisy Wang, Sales Assisitant

Will Lan, Sales Specialist

Monica Lu, Sales Specialist

Yung wang, Sales-Specilist

Peter Duan, Sales Manager

Email:

sales@xzbearings.com

xzindustry@yahoo.com, xzindustry@hotmail.com.

TEL:

86-21-58362283

86-21-60529153

86-21-61555132

FAX/TEL:

86-21-58362282

Website:www.xzbearings.com

Custom Bearings in 10 Day or less!

Run Longer Run without lube Run without corrosion

Run faster Run at lower total cost Run with less vibration

Run cooler Run without wear Run with less downtime

Industry's present day applications place demands on machinery that could not be imagined as little as a decade ago.

Hybrid Ball Bearing Benefits

High Speed-Oil mist lubricates up to three million DN with reduced skidding, wear, and heat generation: grease-lubricated hybrids up to one million DN. Ion doped races with self-lubricating retainers require no hydrocarbon or flurocarbon lubriction.

Extended Operating Life-3 to 5 times greater than that of steel when properly applied.

Marginal Lubrication-Ion- doped races with self-lubricating retainers require no hydrocarbon or fluorocarbon lubrication. By using dessimilar materials(Ceramic on steel) microscopic adhesion welding is eliminated.

Corrossion Resistance-Ceramic material resists corrosion and galling while thin-dense coating may be used to enhance hybrid.

High Stiffness-Modulus of elasticity 50% greater than steel increases bearing rigidity.

Low Torque-Low fricition,even without conventional lubrication,with extremely find surface finishes.

Long Wear Life-High Hardness of Rc78 greatly extends bearing wear characteristics.

Light Weight-60% Lighter than steel, reducing centrifugal forces and overall system weight.

Special Properties-All ceramic components are:

Non Magnetic

Electrically non conductive