NTN Develop New Constant Velocity Joint for Propeller Shafts(Pic)

Resource from: CBCC Likes:2966

May 11,2009

NTN Corporation (hereafter NTN) has developed a ‘High efficiency and low heat generation ten ball constant velocity joint (HELJ)’ for propeller shafts of FR and 4WD vehicles (hereafter ‘constant velocity joint’ is referred to as ‘CVJ’ )

For propeller shafts of FR and 4WD vehicles, a cross groove type CVJ (hereafter, LJ) exhibits the ability to slide axially to enhance vehicle response, with the benefit of very little backlash in the rotational direction. This type of propeller shaft joint is mainly used to enhance the propshaft and vehicle stability under high speed conditions. In recent years, a reduction in weight and an increase in efficiency have also been required for propeller shafts to improve vehicle function and fuel economy. In addition, low internal heat generation of CVJ's is required because heat dissipation performance around the propeller shaft has been reduced due to compact vehicle underbody packaging for better aerodynamics.

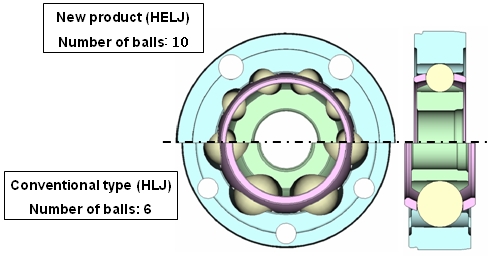

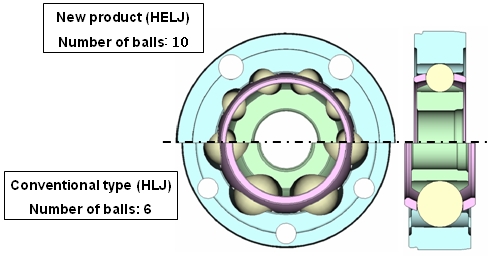

For this new product, the number of balls was increased from six to ten by using smaller a smaller ball size. The inclination angle of the ball rolling groove against shaft axis was decreased, compared with the conventional 6 ball HLJ (NTN‘s current compact cross groove LJ). By implementing these design features, reduced weight and a more compact design is achieved while maintaining strength and durability of the CVJ. Another benefit of the design is the reduction of slide resistance and torque loss during torque transmission (higher efficiency). This is accomplished by internal design optimization of the ball grooves' inclination angle relative to the sliding axis.

In response to an increasing demand of high function capability and fuel economy of vehicles, NTN will market this CVJ globally.

[ Features ]

In comparison with conventional HLJ (with a similar loading capacity)

a. High efficiency

·Torque loss reduced by 50%

b. Low heat generation

·Temperature rise reduced by 50%

c. Light weight

·Mass reduced by 5%

[ Contact ]

Automotive Planning Dept., Automotive Products H.Q. TEL:03-5487-2820

[ New product photo ]

[ Cross-section comparison of new product and conventional type ]]

[ Cross-section comparison of new product and conventional type ]]

()

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

[ Cross-section comparison of new product and conventional type ]]

[ Cross-section comparison of new product and conventional type ]]