NTN Develops “Press Cut Spline Hub Joint”

Resource from: NTN Corporation Likes:3035

May 17,2012

[For lighter, higher performance hub bearings and CVJs. Can be produced on current assembly lines]

NTN Corporation (hereafter, NTN) has developed the “Press Cut Spline Hub Joint” that allows for a lighter weight and eliminates any backlash that often occurs in fittings through the use of a proprietary “press-cut spline method*1” designed specifically for hub joints and constant velocity joins (hereafter, CVJ*2).

Lower fuel consumption has become a high priority issue in the global automotive industry, and one way to achieve this is using lighter weight components for the various systems used throughout a vehicle. Another issue that required addressing was methods used to eliminate backlash between the mating surfaces of hub bearings and CVJ, and to limit stick-slip noise*3 that is often generated with conventional assembly methods.

The newly developed “Press Cut Spline Hub Joint” reduces weight drastically and delivers higher performance based on a new joint method developed based on NTN's high technical capabilities as a manufacturer of both hub bearings and CVJs. Utilizing a proprietary press-cut spline joint for the pre-spline (the smaller spline) inside bore surface of hub bearing reduces the load required for the fitting, and features a bolt to fasten the hub joint and CVJ together. This allows the newly developed product to be used on automobile manufacturer assembly lines without having to change the current 3rd generation hub bearing and CVJ assembly process in use today.

NTN will be exhibiting the newly developed product at the “Automotive Engineering Exposition 2012” to be held at Pacifico Yokohama between May 23 and 25, and plans to market the product globally.

*1 Press-cut spline method:

The spline teeth (pre-spline) that are smaller than the spline teeth formed on the outer circumference of outer ring stem of the CVJ have now been formed inside bore surface of the hub bearing and fastened with a bolt. This new fitting technology allows the CVJ spline teeth to be press fitted on to the hub bearing inside bore surface spline teeth while it is being assembled.

*2 CVJ: Abbreviation of Constant Velocity Joint

*3 Stick-slip noise:

Phenomenon where noise is generated from the contact surfaces of hub bearings and CVJ when torque is transferred from the CVJ to the hub bearing.

[ Features ]

(1) Lightweight : 12% lighter than the current 3rd generation hub bearing + CVJ

(2) High-rigidity : uses the new press-cut fitting method

- eliminates backlash between the hub bearing and CVJ

- limits stick-slip noise

(3) Ease of assembly : same assembly as current 3rd generation hub bearing + CVJ

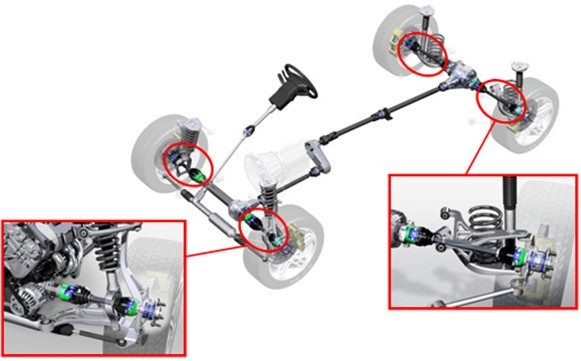

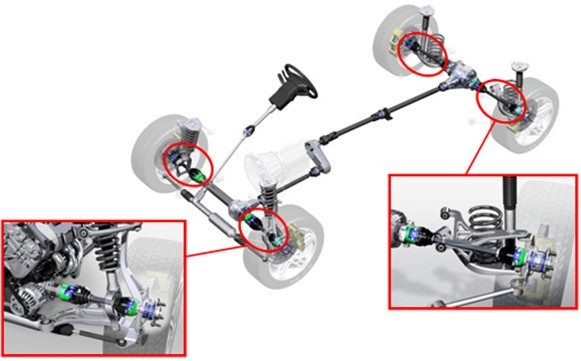

[ Product Photo ]

Press Cut Spline Hub Joint

[ Applicable Parts ]

Press Cut Spline Hub Joint

[ Applicable Parts ]

(NTN Corporation)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

Press Cut Spline Hub Joint

[ Applicable Parts ]

Press Cut Spline Hub Joint

[ Applicable Parts ]